Build your own commercial module part 5: pricing your module

2024-06-26 byocm

So, you've completed your commercial module design. You've spent time and money developing it, maybe you've hired me or another consultant to go over it and make suggestions, and you've lined up sources for parts and manufacturing partners. You're making plans to sell it to your customers. Now, if not sooner, you face an important decision: what's the price going to be?

Pricing your module determines how much profit you will make: the higher the price, the more profit per unit. But it also determines how many sales you can expect. Usually, the lower the price, the more units people will buy. You probably want to choose a price that gives a good trade-off between those two considerations, so as to maximize your overall profit. And there can also be other factors involved.

This is another part in the Build Your Own Commercial Module series, which started with Part 1.

What does "price" mean?

In order to choose a price you need to have some idea of what choosing a price means. It may seem simple that the price is the amount of money people have to pay to buy the product. But who is paying it? To whom? And what exactly does it include?

If you're a manufacturer, you may often be making the product and then selling it to a retailer, who then sells it on to the final customer. The price you charge the retailer is called the wholesale price and the price they charge the final customer is the retail price. Retail price ordinarily needs to be higher than wholesale price because the retailer pays its own expenses, and gets any remaining profit, from the difference between the two prices.

But then there may be further complexity, because maybe - like me - you also sell directly to individuals in the general public as well as selling through retailers. The price you charge those direct customers might or might not be the same as what another retailer charges them, and two different retailers might or might not charge their respective customers the same price for the same module. Then, especially in larger industries (not so often with synth modules) there may also be one or more layers of "distributors" between you and the retailer, each marking up the price as they break down larger orders into smaller orders.

I recently saw a Web forum thread started by someone who was confused to see manufacturers selling products directly to the public at the same prices the retailers were charging. The poster thought a direct from manufacturer purchase obviously ought to be much cheaper; but why should it be? The costs of handling customer orders, shipping, packaging, keeping inventory, and so on still need to be paid, and are likely to be similar whether paid by a retailer or by the manufacturer acting as their own retailer; there are competition-related reasons for the manufacturer not to undercut the retailers' pricing; and there's no reason every business needs to make the same amount of profit anyway. I've also seen forum threads from people who thought on the other hand it was odd that different retailers were charging different (although roughly similar) prices for the same module. But again, why shouldn't they? Their costs are probably different, and so are their markets.

There are questions like what is or isn't included in the price. Is sales tax included? If so, whose sales tax? That will be different between countries in an international situation and even between subnational units like states or provinces in places like the USA and Canada, where subnational units often have their own sales taxes. Is shipping included? To where? Are other "extra" charges, such as duty, customs brokerage, and environmental fees, included? What is the role of promotional discounts in determining the "price" of a product? What about quantity discounts? How is profit shared between the manufacturer, retailer, and any distributors in the middle? Who chooses the prices? When you think you are choosing the price of your product, you need to think about exactly which price you have in mind.

One important benchmark for the price of a product is called MSRP: Manufacturer's Suggested Retail Price. It is pretty much exactly what it says: it is the price that the manufacturer suggests would be a reasonable retail price for the product. Normally, MSRP does not include tax or shipping or other "extras," and it is the price for the quantity a customer typically buys (usually one unit), not incorporating a quantity discount. This is normally the price you're thinking about when you choose the baseline "price" of your product.

MSRP is a retail price. It's how much the final customer pays. If as manufacturer you're going to sell to a retailer, you will sell at a lower price that allows the retailer to mark up the price to get to MSRP before offering that to the final customer. Retail markup in most businesses is around 100%: so you sell at one price and the retailer doubles it. You can turn the calculation around and call it a wholesale discount: 100% markup corresponds to 50% wholesale discount (cut retail price in half to get wholesale).

With small, specialized electronic devices like synth modules, the retail markup is often less than 100%. A typical retail markup for synth modules might be only 40%, which corresponds to a wholesale discount of about 29%. Take your wholesale price and add 40% to get retail, or take your retail price and subtract 29% to get wholesale. But the actual price you offer to or accept from a retailer might be higher or lower; that's down to whatever deal you and the retailer care to make.

As well as the question of prices varying from one seller to another, you may need to think about prices varying over time. All your costs of making your product are likely to increase over time; so how often, if at all, are you willing to increase the price of your product to take that into account? If you don't want to raise your price too often, then you may need to build some extra margin into the price at the start so that you will still be able to make a profit in a few years, when the input costs have gone up. On the other hand, if you are envisioning your product's life cycle as limited to just one or a few "runs" of manufacturing, maybe you can lock in your prices by buying all the parts and other inputs right at the start, and never need to raise the price because you will be discontinuing the product instead of buying more inputs later.

Choosing a price

When I try to set the price for a product or service, I usually go through several different methods of choosing a price, and then at the end I find they all work out to about the same answer. When that happens I figure it's a good sign, strong evidence that the number I ended up with was the right price. I can't promise it will always happen that the different methods give the same answer, but the general idea seems to be good of starting with several different pricing methods to at least get a range of reasonable answers, and then using that range to guide your final decision. Here are five ways to choose a price, and you can probably think of several others.

Dave Jones of EEVblog made a good YouTube video that goes through a lot of the same points I'm covering here, especially focusing on the "cost times a multiplier" method and doing the math for retailer/distributor markup. Be aware, though, that he is mostly talking about larger markets where it's possible to sell more units; selling as many as a thousand in the entire life cycle of a Eurorack synthesizer module is an ambitious goal to say the least, and he wants to do that per year with the Turbo Encabulator.

Cost times a multiplier

By the time you've done development and planned your manufacturing, you should probably have a clear idea of how much it will cost to make your module. It's easy to look at the Bill Of Materials (BOM) and add up the prices you expect to pay for each item, but be careful.

First of all, an electronics BOM usually only lists the electronic parts that go on the schematic - not such things as the front panel and hardware, which still have to be paid for and often make up a large fraction of the cost of manufacturing. If you haven't already, you may be well-advised to make up a real Bill Of Materials, such as would be used in any other manufacturing business except electronics, listing absolutely every physical item in your product. That will also help you with RoHS and similar compliance stuff. And then go through the real BOM and figure out the cost of everything on it.

Second, you need to figure the cost of labour if you're going to pay for that. Maybe you plan to do all the work yourself, and you hope to be compensated for it out of the "profit" (which will be calculated later), but you should think carefully about whether you really want to plan that way, and if so, it may mean you need to aim for a bigger profit later. If you will be involving employees then you definitely need to come up with some kind of estimate of how much of their time will go into the product and how much money that costs.

Third, you need to allow for other costs associated with your product. In particular, the development cost will often be significant, especially for a product like a Eurorack module that may only sell 100 units or less. If it costs a few thousand dollars to develop the design and you sell 100 units then you have to recover a few tens of dollars of development cost per unit - which may be on the order of what you're paying for all the physical parts combined. Of course, to calculate this you need to estimate how many modules you will sell, which was already an important consideration for manufacturing, too.

It's optional to add some more expenses to the estimate at this stage for "cost of doing business" beyond the cost of the module itself, such as Web site, advertising, and so on. I would usually leave these out of the per-module cost estimate, figuring they should be covered out of the "profit" later. But they do need to be covered somehow!

After adding up all these things you have an estimate of the cost of making each unit. Note this is not the same as the book value (discussed later in this article), which your bookkeeper will debit to the account "Cost of Goods Sold" when you actually sell the module. The cost estimate for pricing purposes includes things that would not normally be counted in the book value, so it will usually be higher. It is also, necessarily, an estimate: you don't really know how much money you end up spending until you do spend it, and prices may go up in the future, and you should keep that uncertainty in mind when you prepare your cost estimate and maybe increase the estimate a little just in case.

Once you have a cost estimate, you multiply it by 2.5, and that's your MSRP.

Is it really quite that simple? Well, maybe, maybe not. In the video embedded above, Dave goes through an explanation of why he thinks 2.5 is a good multiplier to use. But you may actually want to use a number that's a little higher or lower, depending for instance on what markup you think your retailers will be getting; whether you are counting your labour in the cost or trying to cover it out of the profit (in which case you need a higher multiplier); what you think the prevailing practice in your industry is; and so on.

I think 2.5 is a reasonable minimum multiplier for use in the Eurorack module industry if you are not trying to cover significant amounts of labour out of the profits, and it now fairly well approximates the pricing of my kit products, which don't require a whole lot of labour (although more than you might think). Pre-COVID my kit prices implied a higher multiplier, but parts costs have gone up and so far I haven't raised my own prices. Using an even smaller multiplier would make sense only if you were scrupulous about including every cost in the estimate to be multiplied, which I usually am not. Using a higher multiplier might be justifiable to compensate for things you left out of the estimate.

I price assembled modules higher even though their physical BOM cost is nearly identical to that of kits, to cover the labour of assembling and adjusting them. That could be thought of as including some labour costs before the multiplier; as just using a higher multiplier; or as a different pricing method entirely, such as the next one.

In relation to other products

Starting from a cost estimate and then multiplying to get to the MSRP is what Dave Jones refers to as a bottom-up method of pricing. It might also be called absolute pricing, because it considers the price of your new module based on what you know about your module itself. Another approach is relative, or top-down, pricing: compare your module to others, find an MSRP that fits into the market the way you want your module to fit into the market, and then work from there back toward the cost and profit margin to make sure the proposed price will be workable. It's relative because the price is determined by looking at other modules more than your own.

One of my pieces of advice for writing a business plan is to make a list of your five most feared competitors, and how your business is similar to and different from each of them. You can do something similar with modules.

If someone was considering buying your module, what other modules would they be looking at instead? Make a list of those, find out their prices, and then decide how yours fits into the list. Think about what patterns you see in the pricing of the other modules, why the more and less expensive ones are more and less expensive, and which kind you want yours to be. Do you want your module to be priced about the same as its near competitors, because that's what people expect to pay for such modules? Do you want yours to be cheaper, so that it will be more attractive to price shoppers? Do you want yours to be more expensive, because you intend to market it as a premium option? Any of those may be reasonable choices; the point is to think them through and make a conscious decision.

When you have multiple products of your own, you can also use your own products as reference points. Often, if I have two products that I think of as being similar size and complexity, I'll give them the same price. For instance, the North Coast Synthesis Octave Switch, Coiler VCF, and Fixed Sine Bank are all 8HP analog modules, and all the same price. Keeping the same price for comparable modules in the product line isn't an absolute rule, however. The Gracious Host is also 8HP, but as a digital module developed during the COVID crisis, and with a lot more features and complexity, I felt it both needed and could support a higher retail price.

Each of my module designs basically requires me to price two products: a kit and an assembled module. I need to choose prices for both of those when I introduce a new design. The labour of assembling the module is almost a product in itself, so when I choose the prices for both the kit and the assembled versions, part of how I do it is by figuring out what I think is the right price for the assembly labour, bearing in mind the complexity of the module, adjustment procedures, and so on. Then I make that be the difference between the kit and assembled prices. I don't necessarily start with the kit and then add, or start with the assembled version and subtract; instead I set both prices at once. But I do it with the idea that I want the difference between them to end up where I think it should be. For my most recent modules I've cut back the kit/assembled gap a bit because I want the kit to be a little less attractive to certain customers who are more enthusiastic about saving money than about actually building a kit. More on this issue in a separate section below.

Depending on how you want to run your business, you can even do relative pricing early in the design and development process. Set out to build a module that fits into a certain market niche; figure out the price it should have and how much it can cost to achieve that price; and then design your module up to that cost. This is an example of something I wrote about in earlier parts of this series, the feedback that can happen between different stages of the design and development process.

Price per HP

Is there a simplified way of pricing modules? Quite possibly. The basic rule is that a bigger module requires more of everything to make: more parts, more labour, more expense to ship, and on the other side of the ledger it probably provides more features and more value to the user. So a bigger module should have a higher price, and just looking at the sheer size of the module might be a good way to guess the price.

The natural way to measure the size of a Eurorack module is by its width in HP: "horizontal pitch," a unit defined to be exactly 5.08mm according to the European theory that if you pretend inches aren't real then they can't hurt you.

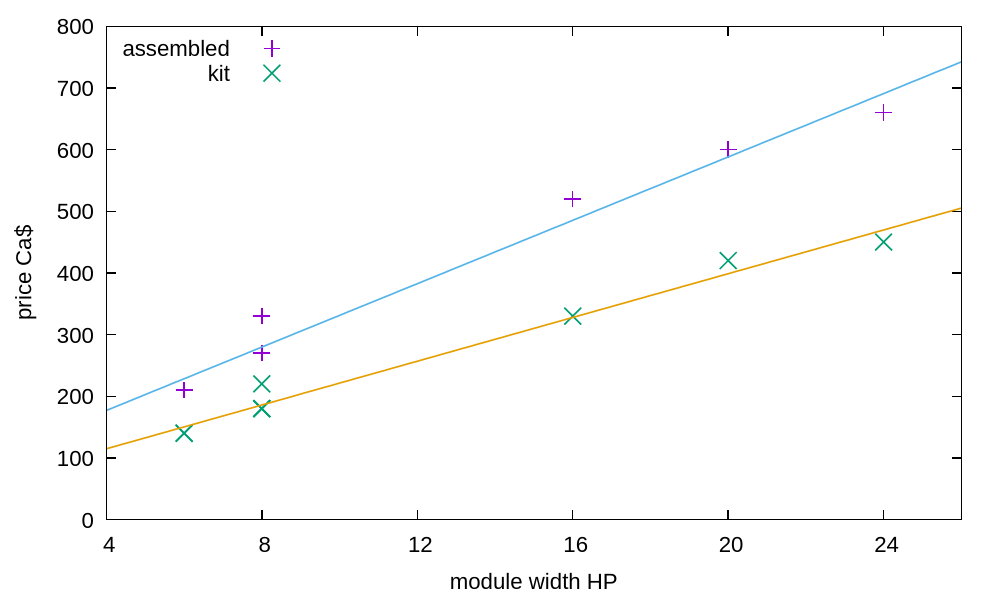

Here's a chart showing the MSRPs of all my current module and kit products, plotted against module width in HP. Note some of these points are multiple (not easy to indicate on the chart) because of multiple products with the same width and price, so the number of visible points plotted are less than the number of products I sell. Nonetheless, the multiple points do count extra for the purposes of the fit lines.

The lines represent linear fits: that is, formulas shaped like "this much as a base price, plus this much per HP" that give the best approximations to the real widths and prices. As you can see in the chart, the fit lines are reasonable though not perfect approximations of the real prices. If you were trying to guess the price of a new North Coast Synthesis module and you knew only its HP width and that it was priced similarly to the others, then you could guess pretty closely by following the formulas.

As with my similar exercise on guessing width based on the front-panel controls and connections ("Reality Check: HP") making a chart like this is really intended to be descriptive rather than prescriptive. It's a way of understanding how I do price my modules, more than a way of telling me how I should price modules. And if you were going to do this kind of study to guide your own pricing, you would probably want to use a different comparison group than just North Coast Synthesis products - perhaps name your competitors (as you should have done already in writing your business plan) and then make a list of their widths and prices.

Still, I'm sure people will want to know the formulas I found, so with the understanding that these are only approximations, I don't commit to use them for my future pricing, and probably nobody else should use them to guide pricing either, the formulas I found are:

- Assembled module price = $74.19 + $25.69 per HP.

- Kit price = $43.87 + $17.74 per HP.

Those formulas are in Canadian dollars, inasmuch as that's the unit of account for my business. The current US dollar equivalents (with live conversions tied into my e-commerce system) are:

- Assembled module price = US$54.39 + US$18.83 per HP.

- Kit price = US$32.16 + US$13.01 per HP.

Price per gram

People joke about modular synthesizers being like an addictive drug ("Eurocrack"). Well then, shouldn't they be priced by weight, like a drug?

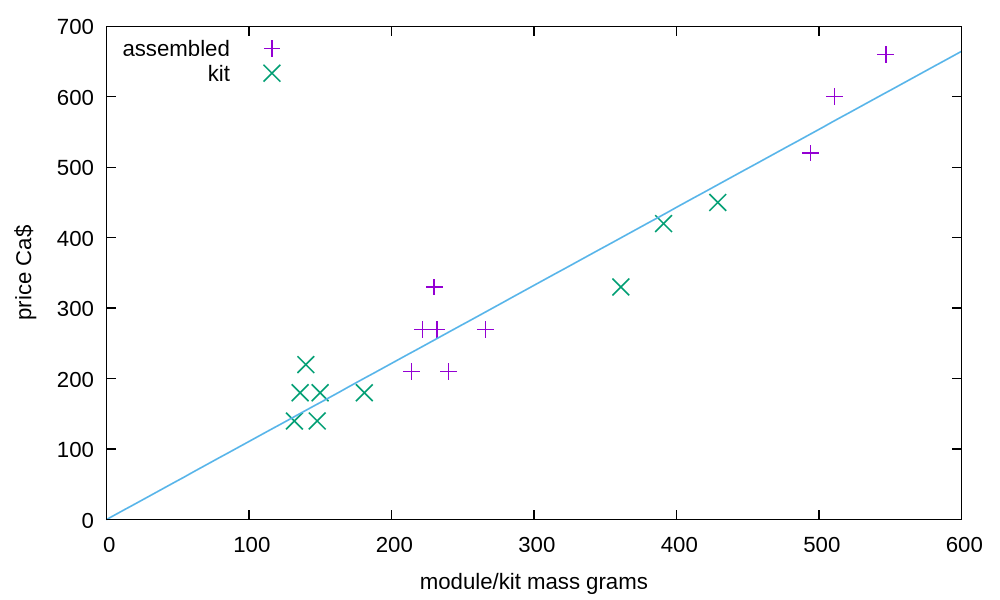

I have a list of all the weights of my products for Customs declaration purposes, because the invoice is supposed to show the net weight of each product. It's necessarily a little approximate because there can be some variation from one example of the same product to the next, for instance if I had a little heavier hand with the solder on one, or if the promotional toys included with the assembled modules (which can vary from one to the next) happen to be a little heavier or lighter. I got the standardized numbers that go into the invoice generation system by weighing multiple examples of each product and taking the average.

From those numbers it's easy to make another chart of price in dollars against mass in grams. The kits and assembled modules form separate clusters on the chart because even though a kit and the corresponding assembled module has the same electronics BOM, the assembled module comes with some extra items and packaging that make it heavier.

When I did the fit lines for these prices I found that the lines for "assembled" and "kit" were so close together it made more sense to just do a single fit on all the data at once. It also made sense to have no "base price" (it would have been less than $5 positive or negative) and call the price just a flat rate: $1.11 per gram (US$0.81 per gram, US$23.09 per ounce).

I think it's interesting that despite different products containing significantly different kinds of materials which would seem to have different costs, such as a fair bit of cardboard included in the weight of each assembled module whereas the kits have less packaging, and despite that a lot of complicated considerations go into choosing the MSRP for every product, the overall result ends up being pretty well-approximated by just a flat price per weight for everything. It's not as close an approximation as the per-HP pricing model, which also isn't perfect, but simply pricing modules by the gram or by the pound would almost make sense.

Pricing of formats and options

When you run a business you probably don't sell only one product. You likely have a line of different products, quite possibly including different versions of what is basically the same product. For instance, I offer assembled modules and do-it-yourself kits. Some Eurorack manufacturers offer special versions of modules, like different front panels; or package deals like entire systems as opposed to individual modules.

I've already mentioned the idea of pricing one product in relation to how you've priced other products, but there's more to be said about what happens in the market when you offer different formats or options, with possibly different prices.

It's basic economics that different customers have different amounts of money and different levels of willingness to spend it. If you price a product at $200 and most of your customers would have been willing to spend $300, then okay, your customers will be happy to get a low price, but you might feel disappointed, because you could have gotten a lot more money by setting the price at $300. On the other hand, if you set the price at $300 and most of your customers would really only be willing and able to spend $200, then they just won't buy, and you make less. It's hard to get accurate information about what customers are willing and able to spend, and that makes it hard to choose the best price to offer.

One of the things sellers often do is to offer several different versions of a product at different prices. One module for $200, and a better module for $300. Then you hope that customers who can afford to pay $300 will choose the $300 product, and customers who can only afford to pay $200 will choose the $200 product. You make extra profit from the richer customers and still make some profit from the poorer ones, and every customer can go away feeling that they were charged a fair price for what they got.

It took me years to learn an important business lesson that might seem like it should have been obvious right from the start:

Don't offer a product you don't actually want your customers to buy.

In particular, if you offer a choice of two or more products, you can't choose which one will be more popular. You have to plan for the possibility that only the least profitable option you offer, will sell at all.

When I first wrote my business plan and estimated prices and sales, I had the idea that I would be selling "PCB only," "full kit," and "assembled" formats for each module. I thought I would be selling those in roughly equal proportions. I tried it, and it did not work well. A few customers bought the assembled version; most bought the PCB version and were angry that it didn't also come with a panel too; and in those early days, nobody bought the full kits.

I had imagined the three formats as offering three different experiences. If you are a hardcore do-it-yourselfer, you want the experience of making your own panel and sourcing your own parts and you get the "PCB only" version. If you are a do-it-yourselfer and want the satisfaction of using something you have built yourself, but not all the work of sourcing parts, then you get the full kit. If you just want to play your music and not to learn electronics at all, then maybe you buy the assembled module. All three kinds of people certainly exist, so I thought I could sell to them all.

What happened was that customers perceived these three options as just three ways of buying the same product, not three really different products. I was competing with myself. Some people who couldn't handle DIY were picking the assembled modules, but those with any DIY inclination would disregard assembled modules entirely and then see the choice between PCB-only and full kit as just a choice between paying more or less money. No surprise that they would choose "pay less money." And then the customers who might really have been good candidates for buying the full kit, ended up getting a product instead that wasn't really appropriate for them, while I got an amount of profit that wasn't enough to keep me in business.

The substitution problem became even more significant when I briefly offered "PCB and panel." Plenty of customers thought that was exactly what they wanted, but it simply didn't work as a business proposition. I would have had to sell thousands of them to make a living, the Eurorack market isn't big enough for that to be realistically possible, and I found I couldn't convince customers that a full kit provided enough extra value over the partial kit, to be worth the difference in price that the costs made necessary.

Now I offer only full kits, and assembled modules. Substitution is still a problem: some customers look only at the price difference without thinking through the other differences between the products, and opt for the cheaper one even though they aren't really prepared to do the assembly themselves. They see the DIY kit price as the "real" price of the module and the difference between that and the assembled version as an "extra." But most customers today have a more realistic understanding of what the difference between kit and assembled really is, and why the price difference is appropriate.

I already said one important lesson was not to sell a product that you don't really want your customers to buy. Ask yourself, if customers were only buying this product and ignoring your others, would that be okay? If your business can't work when your least favourite product sells to the exclusion of others, then you have a problem, because that's what's going to happen eventually.

Another take-away lesson from my experience is that if you will have two products that might compete with one other, it's important for there to be a big enough difference between them, that customers will see them as separate. I wasn't able to sell both "PCB and panel" and "full kit" because they were too close together: customers saw them as one product with an optional extra charge, not as two products. This effect militates against having too many versions of any product. You need to keep gaps between the steps in order to segment the market. "Full kit" and "assembled" seem to be different enough that I can still reasonably expect to sell some of each, though substitution is still a problem.

A third lesson learned is that the price difference between different versions can't be too great, or it will distort customer behaviour. If kits are very cheap in relation to assembled modules, then customers who really can't handle doing the assembly themselves won't be able to resist the apparent "bargain." They will buy the kits, and end up with builds that don't work, tech support cases, and ill feeling. This problem was even worse when I was selling less than full kits, because customers who thought they were going to save money by cutting corners on sourcing, would buy the wrong parts and again they'd end up with builds that didn't work. Part of the value proposition of a full kit, which I try to make clear to my customers, is that with a full kit you actually get good parts - though that doesn't stop some enthusiastic hobbyists from making substitutions anyway.

I have important reasons to keep offering kits, other than net profit; I don't want to drop them completely. But I have toyed with the idea of raising the bar on DIY by pricing my kits the same as my assembled modules. Then only the serious hobbyists who really enjoy building kits as an end in itself, would buy them. Maybe I should even charge more for kits! That's probably not going to happen, but in my more recent module releases I have narrowed the kit/assembled price gap a little - below my first estimate of what the assembly labour should be worth - to try to reduce the amount of attention the kits get from bargain hunters, and encourage people to buy kits only when kits are really what they want.

It doesn't only have to be DIY versus assembled. There are other ways in which you might offer different price levels and different versions. Offering a choice of panel colours raises some manufacturing and inventory issues, but at first glance it seems like something for which customers might be willing to pay a little extra, and it's something many manufacturers want to do. Maybe you can offer limited edition collectible modules, with wooden boxes, and vinyl singles of demo tracks, and other goodies. Some Kickstarter projects have the "extra special version" thing down to a science, and you can look at them for ideas.

Competition among retailers

Most retailers choose to sell near the MSRP, but as the name indicates, MSRP is a suggested price. Unless you get them to agree to some deal saying otherwise, everybody is allowed to sell things at whatever prices they care to, subject to being able to attract customers (so the prices can't be too high) and the fact that they probably want to make a profit themselves (so the prices can't be too low). The fact that MSRP is only a suggestion means competition among sellers remains possible and may cause some annoyance.

Suppose I sell modules to retailers at a wholesale price calculated from MSRP, but then I also sell to the general public myself at the same price. Then the customers might all come to me and not the retailers who are charging the much higher MSRP, and the retailers wouldn't be able to make money. Similarly, if I sell to two retailers at the same wholesale price, but one starts offering deep discounts while the other sticks to selling at MSRP, the discounter may attract all the business, make more money despite their lower profit per module, and the non-discounting retailer would be unable to stay in business.

In an effort to reduce the problem of undercutting each other, it's natural to think that maybe you and all the retailers could get together and agree that nobody will sell the product below a certain minimum price. You can all do better if you protect each other's profits that way. But that's a crime in many jurisdictions, because it is seen as defeating the purpose of the free market. Even if price-fixing happens to be legal right where you are, you're going to run into problems if you try to extend it internationally. That's why we usually keep MSRP "suggested" and not a contractual requirement. Maybe you calculate the wholesale price based on an expected markup to reach MSRP; but after paying it, the retailer is free to set the price they offer to their customers however they see fit. In practice most retailers do sell at MSRP or close, because the standard markup reflects the realities of the business which are more or less the same for every retailer; but in an important legal sense, charging MSRP is not a requirement.

Some manufacturers may attempt to set up a Minimum Advertised Price (MAP). The idea is that the retailers are allowed to sell at whatever price they want, accommodating promotional discounts and such, but they are not allowed to advertise a price below the minimum. Such a deal is still illegal in some places, but it may be legal in some other places where outright price-fixing isn't. I don't think MAP is popular in the synthesizer business, both because it makes things more complicated and because of the remaining legal problems.

One other thing people sometimes do to limit competition is to arrange exclusive distribution contracts. Maybe you agree to sell your products to a retailer in a place like Australia and to no other retailer in Australia. Then Australian customers, who probably want to buy from Australian retailers, will probably go to that one retailer and not buy from overseas retailers, and the one retailer with the exclusive deal is free to set higher prices and make more profit. You might, or might not, make deals with your other retailers elsewhere that they won't sell to Australian customers (preserving the market for your exclusive retailer). This kind of deal is at least more likely to be legal than MAP or outright price-fixing, if you are careful about the terms you set for it. I think I'd still want to talk to a lawyer about it first before committing to details.

My own impression is that with synth modules geographic-exclusivity deals may not make much difference. Customers have a very strong preference never to buy internationally, or at least not from overseas sellers. I've often heard customers in Europe complain that they "can't" buy my products because my European dealers don't carry the items they want, and there's not a lot I can do about that. "Can't buy" in such cases seems to mean they are unwilling to pay their own country's value added tax when the package crosses the border. Nothing else stops them from ordering the products direct from me - I even offer free shipping - and they'd be paying the tax anyway if they ordered from a local retailer, just at a different point in the chain. Customers in the USA seem not to be so concerned about sales tax, but they find other reasons to disregard international mail order.

So if there is one retailer carrying a product in a given country, then they will get basically all the customers in that country, even if I don't bother telling retailers elsewhere "don't interfere with this exclusive deal." And lining up new retailers is difficult enough that only in the biggest markets (like the USA) will I put effort into looking for a second retailer when I already have one, even without a formal exclusivity deal. Between those points and the legal considerations that might come into play, if a retailer came to me asking for some kind of exclusive deal I'd be willing to consider whatever they were offering for it, but I wouldn't expect to be enthusiastic to agree. It just seems like needless complexity.

Don't sell "at cost"

There's a scene in Miracle on 34th Street where Mr. Kringle wants to buy an X-ray machine as a Christmas gift and the businessmen offer to help.

"Let me handle it," said Mr. Gimbel eagerly. "We'll get it for you wholesale!"

"We'll get it at cost!" said Mr. Macy.

Mr. Gimbel comes off sounding like a Grinch for trying to earn a profit on the back of the charitable effort, but that's not fair, because he's not wrong. Mr. Macy is actually offering to donate part of the expense of the machine from his own business's resources, which is a nice gesture but not one he can afford to make too often.

From time to time people come to me with different kinds of stories for why I ought to sell them products without making a profit on the sale, either as a charitable thing or because they're offering me something else of value like a promotional video that ought to compensate for the absence of monetary profits. They usually phrase what they're asking for as selling the product "at cost"; it seems that in ordinary language, most people think to sell at cost means to sell with no profit or loss. My policy is that I will not sell things "at cost"; if there's a good reason then I will either offer to sell at wholesale like Mr. Gimbel, or just make them a gift of the product outright, no charge. You can of course make your own decisions for your business, but I think refusing to sell "at cost" is a good policy.

The first problem with a sale "at cost" is, what exactly does that mean? If we're pursuing the colloquial meaning of "no profit or loss" then we have a lot of tough questions to answer regarding what should count as part of the "cost." We can get a clearer answer by treating "at cost" as a specific technical term with a well-defined meaning, but that meaning may not be the right meaning for the purpose.

If I'm selling something like a synthesizer module, then there are parts in it that I have to pay for, like circuit boards and the electronic components that go into them. Those certainly seem like they should count as part of the cost of the product, and I can calculate that part of the cost relatively easily because I know how many of each item go into each product and how much I pay for those items. (Even this part is not actually quite so simple as it sounds, but it's relatively simple.)

But then there are things used in making modules that are in the nature of bulk supplies, such as solder and cleaning solvent. Solder comes in large spools. I might finish about one spool per year; but I buy several at a time and so I usually have spools on my shelf that are paid for but won't be used very soon. I don't know exactly how much solder goes into each module. Instead, I keep track of it by weighing my currently-in-use solder spool every so often, subtracting to find how many grams have been used since last time, and then debiting the price of that much solder (as a proportion of the price I paid for the full spool when I bought it) to a "solder expense" account. Cleaning solvent is handled similarly.

Solder expense is not associated with individual modules. And that is largely a function of how I have set up my account books. Other businesses might do it differently, for instance by actually trying to track the solder to individual modules; by measuring solder only at the level of entire spools (count a spool as "used" and an expense as soon as you break the seal on it); or even expensing the solder on a cash basis as soon as it is paid for, long before it's used. There are complicated reasons a business, possibly on the advice of an accountant, might choose one or another of these methods.

Many manufacturers will treat small parts like resistors as if those were also bulk supplies like solder. Every so often count how many you have, record an expense for how many were used since the last count, and that is part of the cost of doing business. Whether it's better to do it that way, or to count individual units when they're used like I do, again depends on complicated business considerations. The rules of accounting are mostly aimed at making sure you have a policy and you follow your policy consistently, rather than saying what your policy ought to be, and the right answer will be different for different businesses.

Similarly, should the labour of assembling a module be counted as part of the cost of the module, and if so, at what rate? If I were paying a contractor a fee per module to assemble them, then it seems clear that that fee should be part of the cost of the module. But if I'm paying an employee a salary per month to assemble modules, it's difficult or impossible to trace how much of that salary went to assembling each module. My employee probably assembles several different kinds of modules and does other paid tasks besides assembling modules; it's hard to say how much of their salary pays for each module in particular. In the books it would be recorded in a different account entirely, not as part of inventory.

What about the cost of development? If you spent $10,000 to work out the design of your module, and you plan to sell 200 of them, you need to recover $50 of development cost per module on average. You definitely need to count that as part of the "cost" when you are setting your "manufacturer's suggested retail price" (as discussed above) but should it be included when you are selling a module "at cost"? That's less clear, and it's one reason that the cost estimate you may have used in choosing your MSRP, cannot be re-used to inform a sale "at cost" - you have to do a new calculation.

Then there are all the other costs of running a business that are not directly associated to specific products, like the fees paid to host your Web site. Are those part of "cost"? If they're not, then selling "at cost" wouldn't mean breaking even, it would mean running at a substantial loss. But someone who thought they deserved to buy "at cost" could reasonably say that it should not include paying for anything except the product.

There was an interesting Manitoba court case, Wright et al. v. Lemky et al., 2023 MBKB 140, in which one party agreed to sell oil "at cost" to another party. The deal fell apart, mostly over other issues, and the court had to visit the question of what selling "at cost" really means. The sellers were apparently selling oil at a higher price than what they had paid for the oil, the buyers objected to that because the deal was supposed to be "at cost" and they thought that should mean only the money that was actually paid to buy the oil, and the judge (raising some of the points above, such as cost of labour) found that it wasn't possible to determine what "at cost" should really mean in the context of the contract, so there could be no award of damages on that particular point.

With all due respect to the judge in that case, I think the court decision may have been wrong about selling "at cost." Selling "at cost" does have a clear and specific meaning generally understood in the business community, so if that's written into the contract it should be possible to say whether the contract was carried out or not. Selling at cost means selling at book value. The problem is that book value, although perfectly well-defined, is not a sensible price at which to sell things, and it does not reasonably correspond to the goal of "no profit or loss."

Whenever I sell a product, I make an entry in my account books, credit "inventory" and debit "cost of goods sold," representing the value of the product I just sold. That amount, however it happened to be calculated, is the book value of the product. If I also collect that same amount from the customer (credit "revenue," debit "cash") then I have sold the product at cost. And then the naively-calculated profit (credit balance of revenue minus debit balance of cost of goods sold) would be zero and it might appear I made no profit or loss on the sale. Mission accomplished, right?

The problem is that the book value is only meaningful in the context of the books. It depends on a lot of other things. I keep my books in such a way that book value includes all and only those costs I directly trace to the individual products - so it does include things like resistors and it doesn't include things like solder and labour. Book value does not include any development cost because that was all paid for and recorded in other accounts during development. But if I were treating resistors as a bulk supply instead of individually counted units, then the book value might not include them after all, or I might have to come up with a different way of calculating book value (such as making an estimate instead of adding up other costs).

Book value depends on how I set up my books, whereas the true "cost" logically shouldn't. The purpose of my bookkeeping isn't to assign the most perfectly accurate value to each individual product; it is to track the overall performance of my business for management and tax purposes. The overall numbers are correct, and the per-item numbers are just what they need to be so that the overall numbers will be correct and my accounting policies will be practical and legal.

Note that it doesn't really matter to my overall profit whether I count a given cost as part of the book value of the product, or as an expense in a separate account, because it's all going to be part of the total expenses set against total revenue eventually anyway. At most, this decision may bear on the timing of when the expense is recognized (which may have tax consequences), and the standard accounting rules and the relevant tax laws are intended to make that part work out as sensibly as is possible. But it does make a difference if I'm trying to sell things "at cost."

Trying to extract just one number, the book value of a specific product, from my accounts and use it in a totally different context to represent "the fair price at which I don't make a profit or loss" is a doomed exercise. And unfortunately, there may not be any easy way to get a better number for that purpose. Businesses don't really make profit or loss on single sales: they make it on the business as a whole. Many expenses can only meaningfully be evaluated on that larger scale. Any attempt to calculate a price for a per-item profit target of zero, will be somwhat in the nature of fiction.

If you really want to give someone a special price representing "no profit or loss" then a halfway reasonable thing you might do would be to offer them what's called "cost plus." Add a percentage like 10% or 15% on top of your book value, and hope that's close enough. It may be a reasonable estimate given that an exact calculation is not possible.

I think cost plus is more fair than only charging the book value, which would be what "at cost" actually means. But your customer who thinks "cost" means "no profit" is likely to think cost plus means you're gouging them for an extra 10% or 15% of profit, and they won't be grateful. The 10% or 15% markup isn't really a profit. It is a (usually low) estimate of the other costs that are not captured in book value because of the special way accountants calculate book value. But try explaining that. I prefer to avoid the issue by either giving away products for free when I think it's really justified, or by offering to sell at the price I would offer to wholesale customers, if I'm willing to offer a deep discount but not a freebie.

◀ PREV The varieties of ribbon cable experience || Currency options in the Web storefront NEXT ▶