DIY no-clean-style flux

2019-06-06 SDIY chemistry science!

My two previous DIY solder flux formulations are both designed to be cleaned away after use, with alcohol or with water. In both cases the cleaning is more or less necessary: traditional resin leaves a sticky residue that will attract water, and the citric-acid water-wash flux remains active and corrosive at room temperature, so it will damage boards if left in place. But there are many solder joints, such as those involving stranded wire or liquid-trapping components like potentiometers, that cannot or should not be cleaned after soldering. Those mandate a no-clean flux.

The flux I'm describing here is somewhat experimental. It is partially inspired by US Patent 5,297,721, but also incorporates some ideas from other patents, known formulations of commercial fluxes, and the compromises necessary to make it something you can reasonably mix up in a home lab. Please note that fluxes similar to this one are sold on the claim that they work without cleaning, but I'm not sure I want to commit to that really working, and so I am calling it "no-clean style" rather than promising that it will really work perfectly well without cleaning. In my testing, residues from fluxes made to this formulation have allowed significant leakage currents that might interfere with circuit operation. It may be better to treat this as a water-wash flux. See my next article for the test results.

Laxatives and supplements

As described in the first article of this series, one of the fundamental flux ingredients is the resin: a gooey or plastic-like substance that will become a thin liquid under soldering heat and flow out onto the joint, possibly carrying other ingredients with it. Pine rosin, or the resin from which it is derived, is the old standby for this purpose. Synthetic fluxes that avoid rosin often replace it with polyethylene glycol (PEG). The paste filling of no-clean flux-core solder is often just some grade of PEG, possibly with a small amount of an activator added, much as rosin flux might contain an activator.

Polyethylene glycol is not to be confused with ethylene glycol, commonly used in antifreeze. The connection between them is theoretical: PEG has the structure that would result if you joined molecules of ethylene glycol into a polymer, and that determines its name, but PEG is not in fact manufactured by polymerizing ethylene glycol in practice, but rather by polymerizing ethylene oxide.

The properties of PEG vary depending on how many ethylene oxide molecules were joined to create each PEG molecule, so when PEG is used in industry, it's not just "PEG" but PEG with some number, such as "PEG 400" or "PEG 3350." Each of these will inevitably be a mixture of different-sixed molecules, but the number describes the target value for the average molecular weight. With PEG 3350, each PEG molecule has about 76 ethylene oxide units in it.

PEGs up to about 1000 are liquid at room temperature (getting thicker and stickier as the number increases). They tend to be good solvents that will mix with both oil and water. Many fluxes use a low-molecular-weight PEG as the main solvent and dissolve whatever other ingredients are required into it. Past molecular weight 1000, we're dealing with solids, which go from soft and waxy up to hard and plastic-like; but they remain water-soluble even up to very high molecular weight. All the PEGs are basically non-toxic, and they're commonly used in a number of pharmaceutical and food-additive applications, for stuff like coating pills. They also have many niche uses - for instance, woodworkers and archaeologists sometimes stabilize wood by soaking it in PEG 400 or PEG 1000 to replace the water with something that won't evaporate.

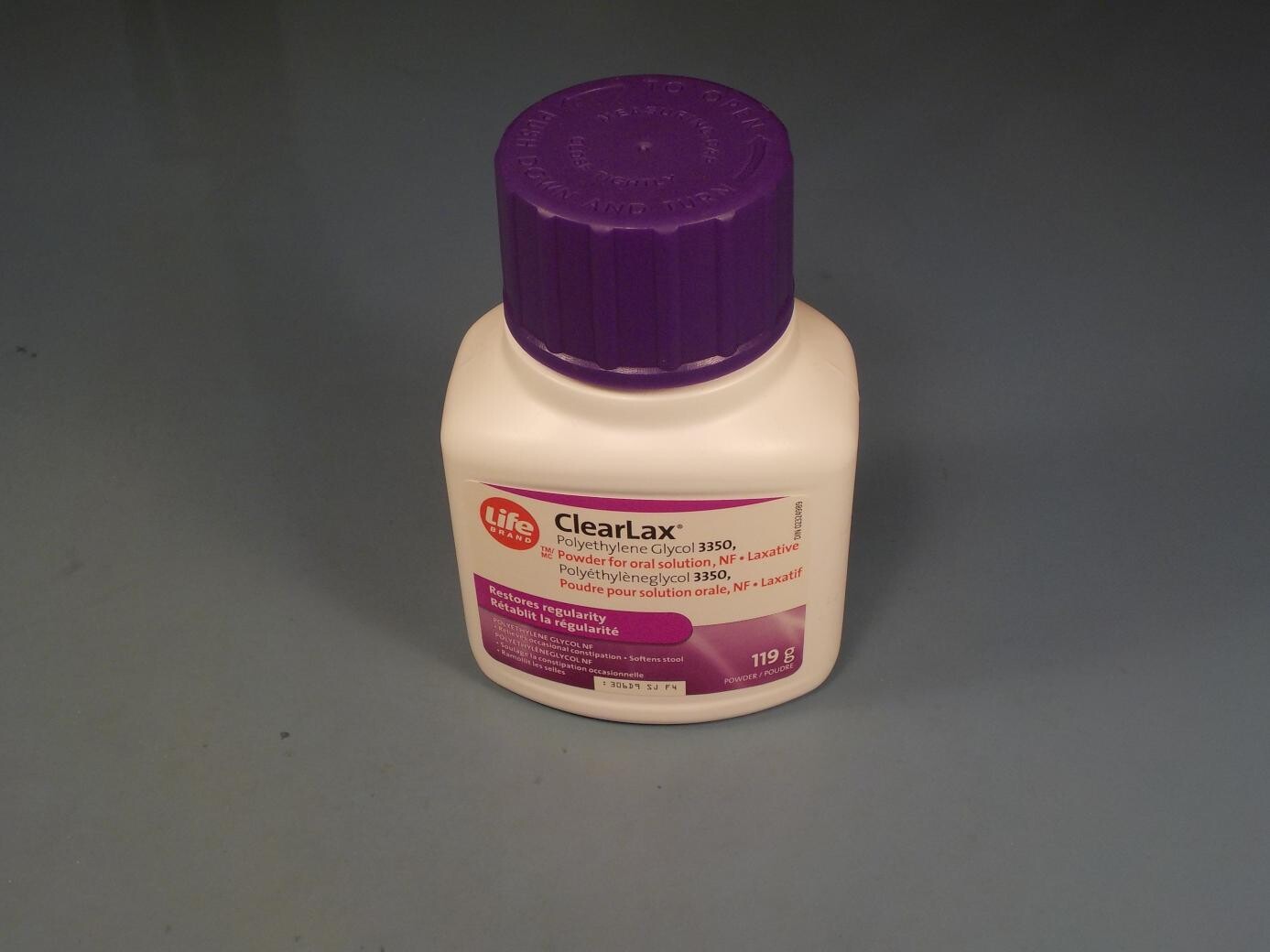

I wanted to use a solid PEG as the resin in my no-clean flux formulation, but I was faced with how to obtain that and how to direct do-it-yourselfers to do the same. The answer turned out to be PEG 3350. It's commonly sold in drugstores as an over-the-counter laxative. The intended use is that you mix 17g of this stuff (which is a substantial amount) into a drink, swallow it, do that once a day, and it keeps everything moving. It is basically an artificial form of dietary fibre: something that won't be absorbed in your intestines and creates osmotic pressure, limiting water absorption. In many places you can buy pure PEG 3350 powder for this purpose quite cheaply under a name like "ClearLax," "RestoraLax," or "Macrogol."

In researching this, I learned that another common medical product is "PEG 3350 with electrolytes," often sold under the name "Colyte." That's used as a laxative and to flush out the intestines before procedures like colonoscopy, I think. I'm not sure that the "with electrolytes" version is commonly sold over-the-counter, that is, to the general public. But my guess is that in some places it may be possible to find that and not pure PEG; and if you were in that situation, you'd have a bit of an issue because the "electrolytes" are going to be things like sodium chloride. Any chloride is bad news in a no-clean flux because it will support corrosion.

So even though I'm not sure how applicable this is to most readers, I ended up doing an experiment on purifying PEG by removing the electrolytes from a "with electrolytes" product. If you need to do that, or just find the subject interesting, you can go watch the video for it.

Unlike rosin, PEG is not self-activating. If we use it alone on a solder joint, it will only have a very limited fluxing effect. We need to add something else to activate it, and the activator should ideally be something that will function as an acid or other corrosive kind of chemical at high temperatures, but be well-behaved and neutral at room temperature. It also, obviously, has to be something we can actually obtain, not too poisonous, compatible with whatever we're using as solvent (in this case, water), and so on.

Citric acid, the main activator in the water-wash flux from last entry, might be one good choice. I ended up putting a little bit of that in my no-clean flux because I hope that in small amounts it will help reduce corrosion by chelating metals (especially when the flux is formulated with tap water). I feel justified in using it as one ingredient of a no-clean flux because it's recommended as such in that patent I mentioned before. But I think it's too corrosive to be the main activator, or used in larger quantities.

Instead, I opted to make the main activator be some form of amino acid. An amino acid in general contains both an organic acid group and an amine (which functions as a base, the opposite of an acid) in the same molecule. At low temperatures they basically neutralize each other, making the substance relatively inactive. At high temperatures, both groups become active, giving the effect of both an organic acid flux activator and an amine activator in the same ingredient. That's what it takes to be a good activator for no-clean flux.

And the other really nice thing about amino acids is that they are non-toxic and easy to obtain. You can get a whole menu of food-grade pure amino acid powders at relatively low prices from a "sports nutrition" vendor, because some athletes, body-builders, and so on like to consume pure amino acids as dietary supplements, hoping to get some kind of performance enhancement. (I'm not going to comment very much on that, but you might ask yourself: if these products really worked as performance enhancers, then why aren't they banned as drugs by the sports governing bodies?)

Here are my suggestions for amino acid activators to be used in DIY flux. I have not tried all of them. They are ranked in order from what I expect on theoretical considerations to be most active, to least. All of them should be commonly available from health food or sports nutrition vendors.

- Betaine, also known as trimethylglycine (TMG). This is an amino acid with methyl groups substituted onto the amine. Claimed to support liver function as a dietary supplement. May be called "anhydrous betaine" or (incorrectly, but the vendors do use this term) "betaine anhydrous." Don't use a "hydrochloride" or "HCl" version, claimed to be a digestive aid, because that - although likely even more effective as a flux activator - is too corrosive for a no-clean flux.

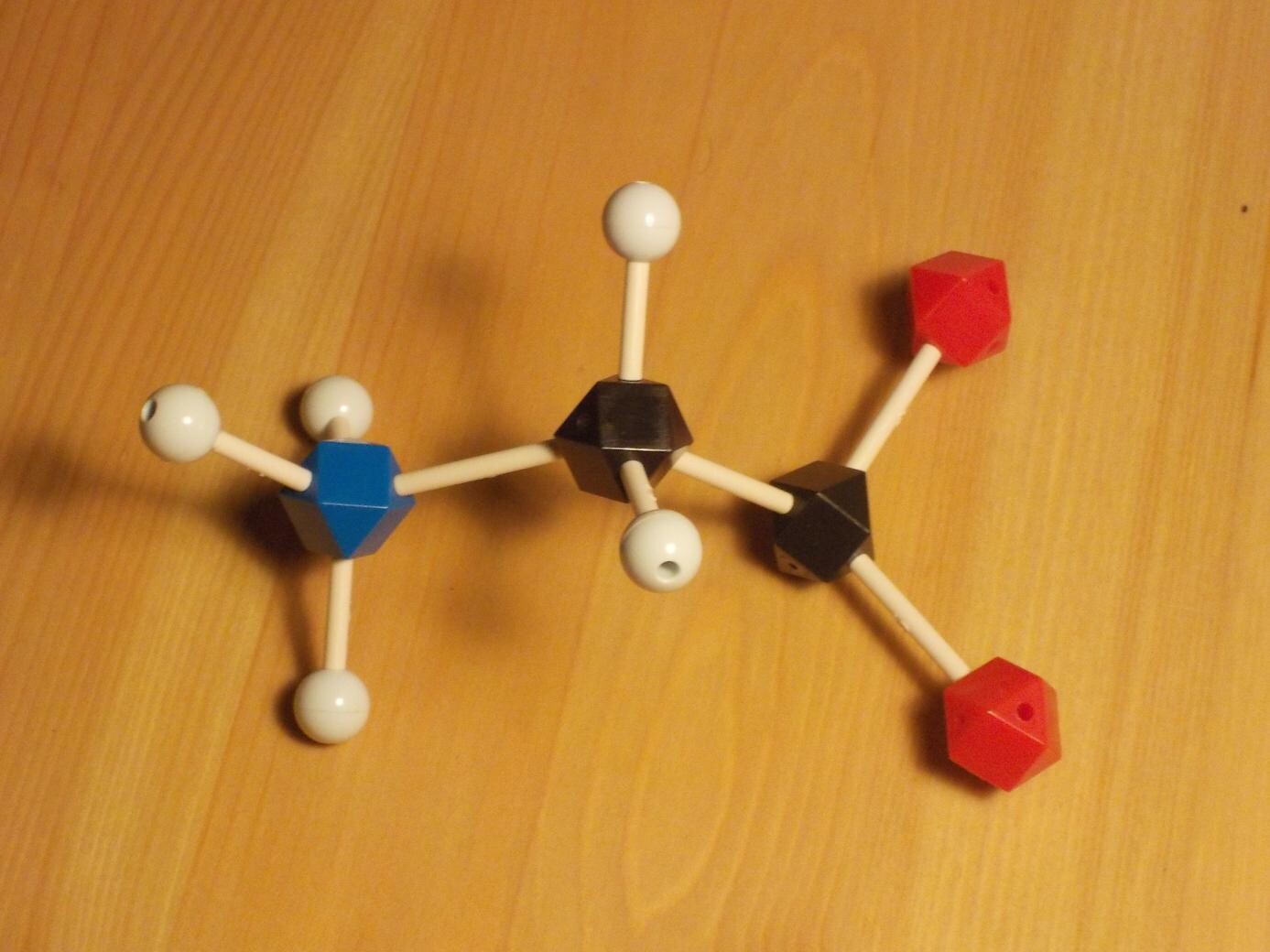

- Glycine, the simplest amino acid, claimed to help build muscle mass. This is the one shown in my molecular model above.

- Alanine, which is the same thing as alpha-alanine. The name may also have a prefix like "L-," "D-," or "DL-"; these prefixes refer to stereochemistry and are relevant for its biological function but should have no effect on its flux-activating properties.

- Beta-alanine, which is not the same thing as alpha-alanine, and expected to be a little less active in flux. Claimed to help delay fatigue during workouts.

- Gamma-aminobutyric acid (GABA), which is a neurotransmitter and claimed to help promote better sleep when used as a dietary supplement.

In my experimental fluxes, I tried making a batch each with 3% of betaine and beta-alanine, the idea being to compare them in a future experiment.

Patented and commercial flux formulations of this kind often include some kind of surfactant to make the water-based liquid wetter and easier to apply. I considered trying to put something like that into mine, but decided against it. They are not easy for private individuals to obtain in small amounts and a consistent way. My first thought was to suggest adding a drop or two of dish detergent, but many of those products contain sodium chloride (which makes them thicker by changing the properties of other things in the mixture) and I'm trying hard to avoid chloride. Even if I found a product (automatic dishwasher "rinse agent" was another candidate) that I felt good about, making sure everyone in an international audience could obtain the same thing would be hard. So I'm leaving that out and you can do experiments of your own if you wish. One paper I read suggested that the PEG itself is a surfactant to some extent, although the 12% concentration I chose (hoping for a relatively thick liquid) is somewhat too high for that effect to be really strong with PEG 3350. Experimenting with a lower concentration might be worthwhile if it turns out that the mixture isn't wet enough.

Making the flux

Here's my experimental formulation for a no-clean-style flux with PEG resin and amino acid activator. Percentages are by weight.

- PEG 3350 (or any PEG from 2000 to 5000): 12%

- Activators: any of betaine, glycine, alanine, beta-alanine, or GABA, or a combination of these, totalling between 1% and 5%

- Citric acid: 0.5%

- Potassium sorbate: 0.2%

- Tap water: to make 100%

Combine ingredients and mix until dissolved. I was using PEG in large solid chunks from my earlier purification experiment, and I found the easiest way to get it to dissolve in the water was to just cover it and let it sit a couple hours before stirring. If using powdered PEG it should dissolve much faster.

This flux is intended to be no-clean, but I'm calling it "no-clean style" because I don't want to claim too much about how non-corrosive it really is. If you want to clean it off, you should use water - other solvents will not be effective. All ingredients are commonly sold for human consumption and it is as non-toxic as such a thing reasonably can be; but as with any smoke, the smoke produced when soldering with this flux may be irritating.

See comments above about obtaining PEG 3350 (usually sold as a laxative) and purifying it if necessary, and amino acid activators (usually sold as dietary supplements for "sports nutrition"). Citric acid is usually sold as a food or drink additive; see my comments in the water-wash flux article. Potassium sorbate is sold as a fermentation stopper by home brewing suppliers.

In summary, I've described typical ingredients used in modern no-clean fluxes, and my own formulation for a flux of this kind that hobbyists can reasonably make at home. I've also given some notes on how to obtain and purify the ingredients. Stay tuned for a future entry in which I will try out this and my other DIY flux formulations and see how well they work.

◀ PREV Make your own water-wash flux || Testing homemade fluxes NEXT ▶

MSK 010 Fixed Sine Bank, variant A

US$201.26 including shipping

Comments

PEG 3350 is the best choice? No higher number? Because, perhaps 5000 is cheaper (if you need less of it)? What does that actually cost you? Here in the drugstore, 20 sachets of 14.4gr (288gr) cost € 6.95 ($ 8.52).

Is this flux like water? And suitable for reflow under a BGA chip (without reballing)?

No email field ... I hope I will remember to check for an answer.

I found at the local health food store:

"Betaine HT": "Surfactant for shower gels and shampoos", 1000ml Ingredients:> 30% amphoteric surfactants The active washing substance is approx. 30%. Below the symbol for corrosive substances.

and "Glycine Surfactant": Previous trade name: Rewoteric AM2C Use concentration: 5-15% A mild glycine surfactant. The active washing substance is 40%

Mild washing substance 500ml

INCI: Disodium Cocoamphodiacetate

Below the symbol for corrosive substances.

If you find these ingredients difficult to obtain, I'd really suggest starting with the citric acid water-wash flux. It's easier to make and produced better results in my experiments.

I also experiment with DIY fluxes, just done some "no darkening, clear, hi temp resistant flux" based on glycerine and stearic acid. I focus to melting, boiling and burning point of used integridients, so no based on water.

See some video https://www.youtube.com/watch?v=xCuPTHsScpA

Also, very good and proven quality rossin liquid flux can be found in US.PAT.3003901 NON CORROSIVE SOLDERING FLUX, 1961.

Again great article

Regards,

Andrés