tag "byocm"

Build your own commercial module part 5: pricing your module

So, you've completed your commercial module design. You've spent time and money developing it, maybe you've hired me or another consultant to go over it and make suggestions, and you've lined up sources for parts and manufacturing partners. You're making plans to sell it to your customers. Now, if not sooner, you face an important decision: what's the price going to be? READ MORE

Build your own commercial module part 4: manufacturing

I've written a lot about module design because from my point of view, that's the fun part. It's tempting to sit down with pen and paper, draw some schematics and sketches, maybe even build out some of those circuits on the breadboard, and then think you're close to having completed your very own commercial modules. If you have a workable design, then in one sense, you are close to being "finished." But in another important sense, it means you're just ready to start doing the real work: because with a finished design, then you still face the question of how to produce modules to that design in commercial quantities, and get people to pay you for those modules. READ MORE

Build your own commercial module part 3: firmware and documentation

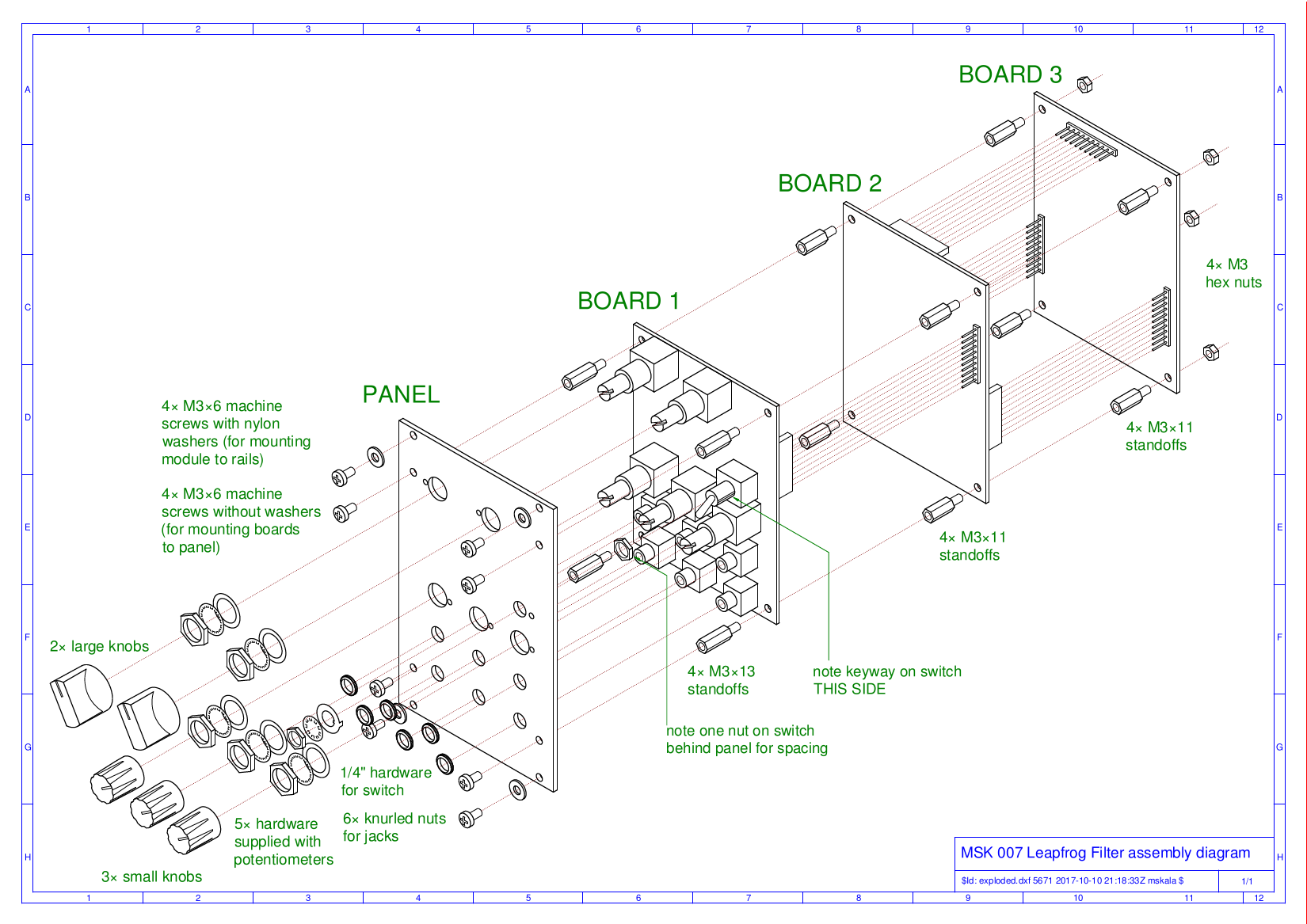

There's a lot more to a commercial module design than just the physical module that you can touch. If, as is the case with many new designs, the module includes any kind of computer, microcontroller, or other programmable device, then you need to have the program for that device. Usually, the program will be called firmware - software that becomes part of the hardware. Even a module without a conventionally programmable CPU in it may need something like an FPGA bit stream. Even a basically analog design may have some programmable aspect. For instance, my Leapfrog VCF design was originally intended to be programmable for different filter curves by substituting different resistor values on one of the three circuit boards. Creating this intangible programming information is part of creating the module, but also separable from the main task of circuit design. READ MORE

Build your own commercial module part 2: design and development

Once you have a clear idea of what commercial module you're trying to build, the design concept as described in the first part of this article series, you face the task of turning that concept into a design as such: an electronic circuit with all the details specified so that it can be manufactured on a commercial basis, with all the necessary side items like the layout of a printed circuit board, information on where to get all the parts, physical shapes of things like panels, and so on. This kind of design work is critically important to the success of the product, but it also demands a lot of technological skill, so it's often the stage where it makes sense to bring in a consultant to help. READ MORE

Build your own commercial module part 1: the design concept

There's a pretty natural progression in the modular synthesizer hobby (the addiction, if you prefer). People start out buying commercial modules; maybe they go through a few rounds of selling off modules that they find just aren't quite right; eventually, they come to the idea of wanting to build their own modules with exactly the features they want; and although doing DIY just for oneself is a viable hobby too, many hobbyists want to take the next step, of going pro and building and selling their own commercial modules. READ MORE