tag "SDIY"

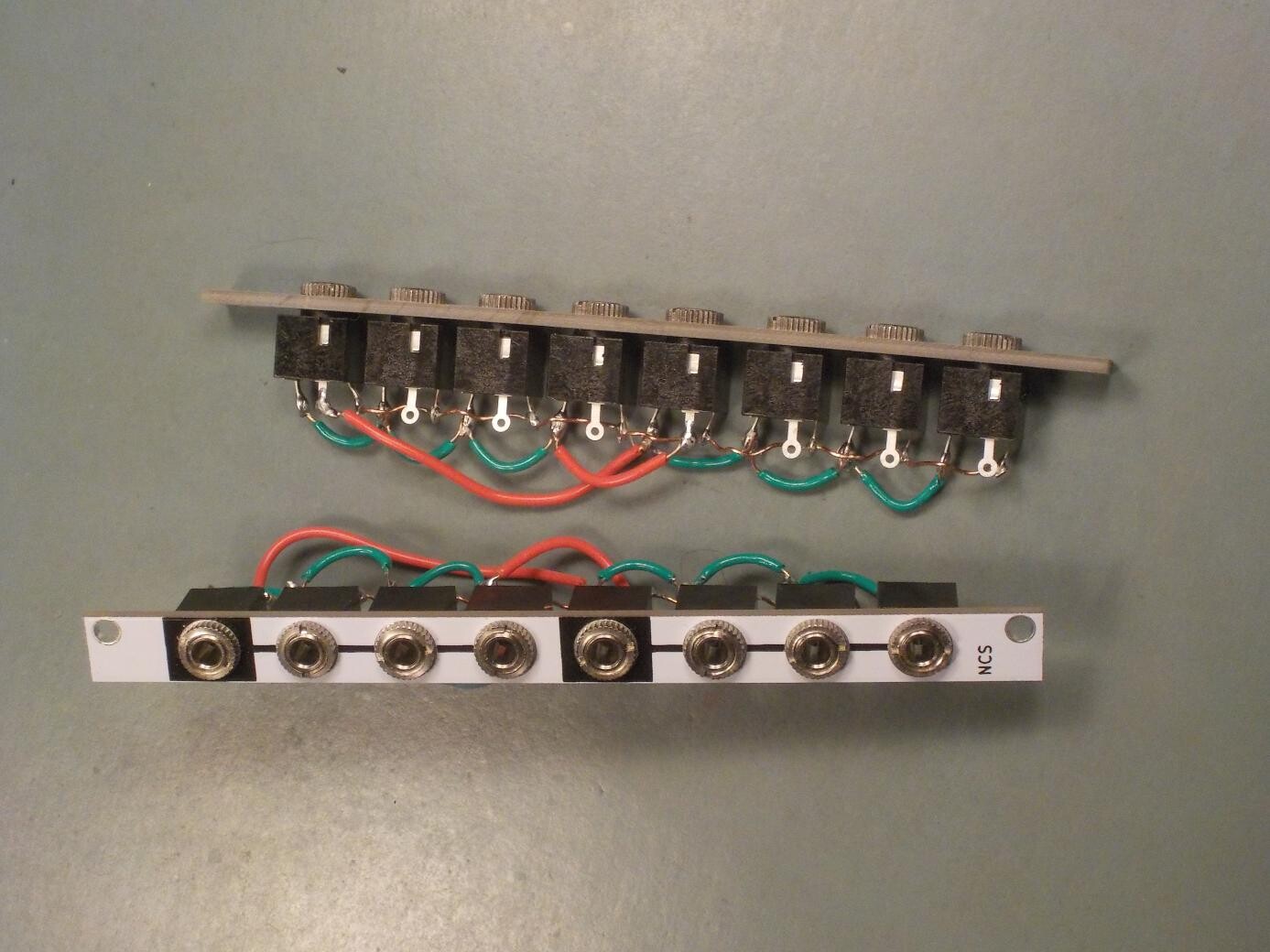

Passive multiples and friends

Passive multiples are often recommended as first synthesizer do-it-yourself projects. There are a few reasons for that: they're simple modules without too many things that can go wrong; they're useful modules that almost everybody needs; the parts don't cost a whole lot; and they're an opportunity to practice soldering. READ MORE

New look for DIY kits

If you've been following the North Coast Synthesis email newsletter you'll probably know that I've had ongoing quality problems with the knobs I use in most of my products. The main issue is with the setscrews used to hold the knob onto a shaft: in many instances, the threads are stripped, or so weak that they immediately become stripped when tightened, so that it's not possible to attach the knob securely. The problem becomes clear as soon as the knob is installed, so although it is not good in the case of modules I sell assembled, at least with those I can recognize that the knob is bad, replace it, and be sure of shipping a good one to the customer in the finished product. It's more serious with knobs that ship unassembled in my Eurorack SDIY kits, because then it may be the customer who discovers the problem. READ MORE

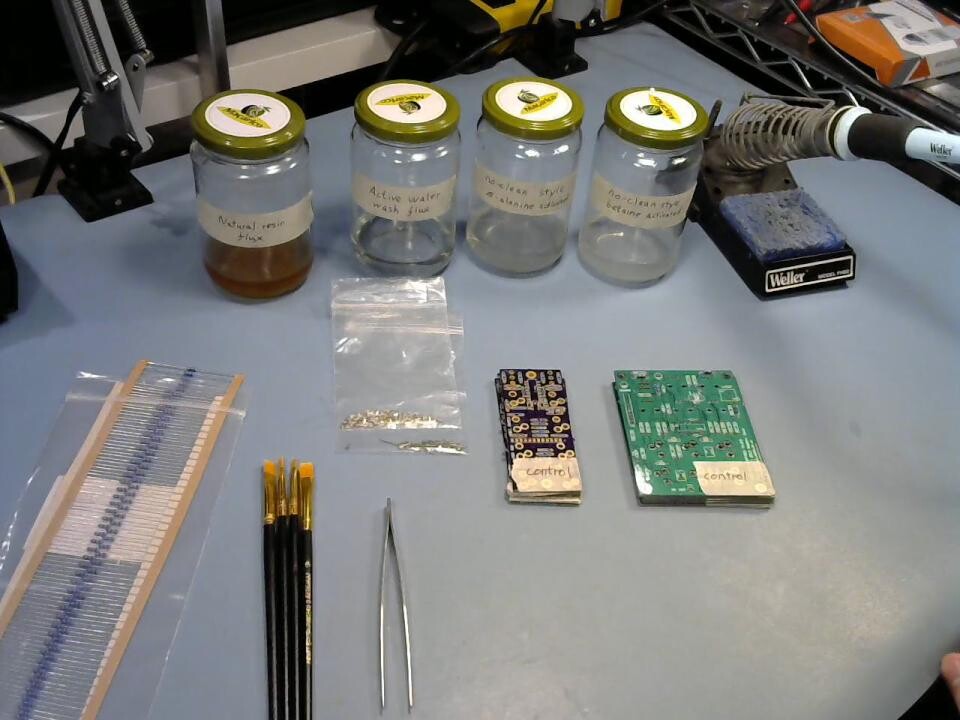

Testing homemade fluxes

In the last four articles (start here) I've gone through a lot of the technicalities of flux: what's in it, how it works, and how to make your own. Now, let's bring it together and try out all these experimental fluxes. READ MORE

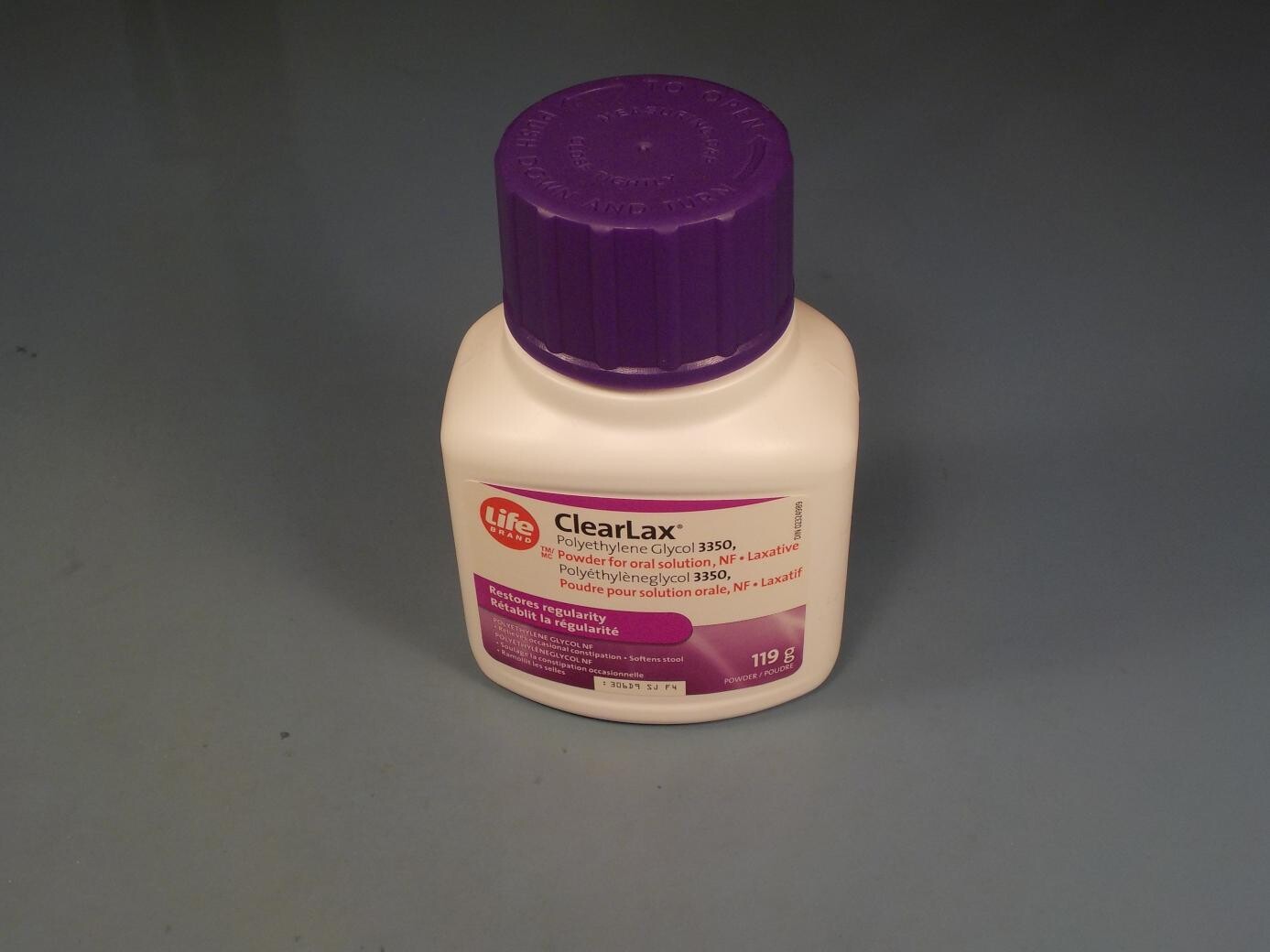

DIY no-clean-style flux

My two previous DIY solder flux formulations are both designed to be cleaned away after use, with alcohol or with water. In both cases the cleaning is more or less necessary: traditional resin leaves a sticky residue that will attract water, and the citric-acid water-wash flux remains active and corrosive at room temperature, so it will damage boards if left in place. But there are many solder joints, such as those involving stranded wire or liquid-trapping components like potentiometers, that cannot or should not be cleaned after soldering. Those mandate a no-clean flux. READ MORE

Make your own water-wash flux

The current trends in electronics are to smaller and smaller surface-mount components; lead-free solder alloys and a diversity of surface platings; higher temperatures which mean soldering must be faster to avoid component damage; and avoiding toxic or environmentally-damaging cleaning solvents. All these trends make traditional solder fluxes, like the one in my last article, less effective or appealing. In this article, let's look at water-wash fluxes, which address some of the issues of the older style. READ MORE

Homemade traditional resin flux

For most of the history of electronics, rosin has been the main ingredient in electronic solder flux. Anybody who learned electronics Back In The Day™ will be familiar with the piney smell of solder smoke. In this second article of the series on flux, we'll look at how to make your own traditional rosin or resin flux. For some background on the chemistry and physics of how flux works, see Part 1: "What is flux?" READ MORE

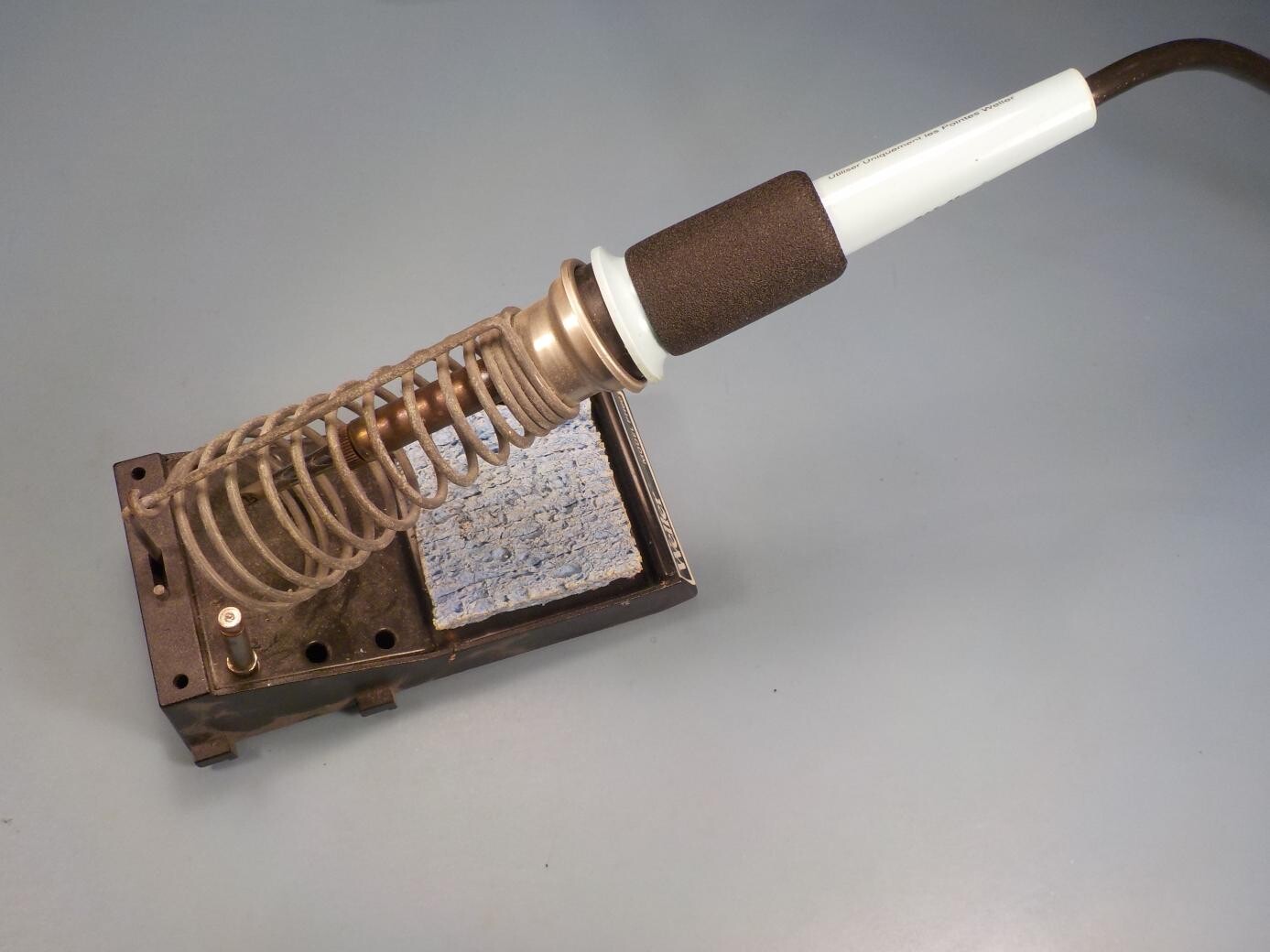

What is flux?

The details of soldering are always popular discussion topics in synth DIY fora: what kind of soldering iron should I use for building something like a Coiler VCF kit? What temperature? What kind of solder? And that last topic, in practice, is often really a discussion of what flux to use, because flux is usually built into the solder and the differences among fluxes are often the most important differences among solder products. There's been a lot written on recommendations for what kind of flux to use in different SDIY applications, but in this entry I'm going to take a different perspective on flux: the chemistry and physics of the flux itself. What is this stuff that we use every day, and how does it work? In planned future entries, I'll go through flux formulations you can make at home, videos of my own experiments with homemade flux, and so on. READ MORE

Common parts to keep in stock

One of the most common beginner SDIY questions is which parts are frequently used and worth buying in large quantities to use on multiple projects. The people who ask this question think they're going to save serious amounts of money by buying common parts in bulk, and although I have serious misgivings about the money-saving aspect, the question isn't going to stop being asked, and there are in fact other reasons why keeping a stock of parts may be a good idea. Here are some thoughts on that. READ MORE

The vanity of "Having A Lot Of Parts"

It is often said that the secret of Taco Bell's success is that they only use six ingredients: refried beans, seasoned ground beef mixture, cheddar cheese, sour cream, lettuce, and corn tortillas. Everything on their menu is just some combination of these six ingredients, and the ingredients are all cheap to begin with and more so when bought in huge bulk quantities, so Taco Bell's cost is very low and their profit margins incredibly high. READ MORE