tag "chemistry"

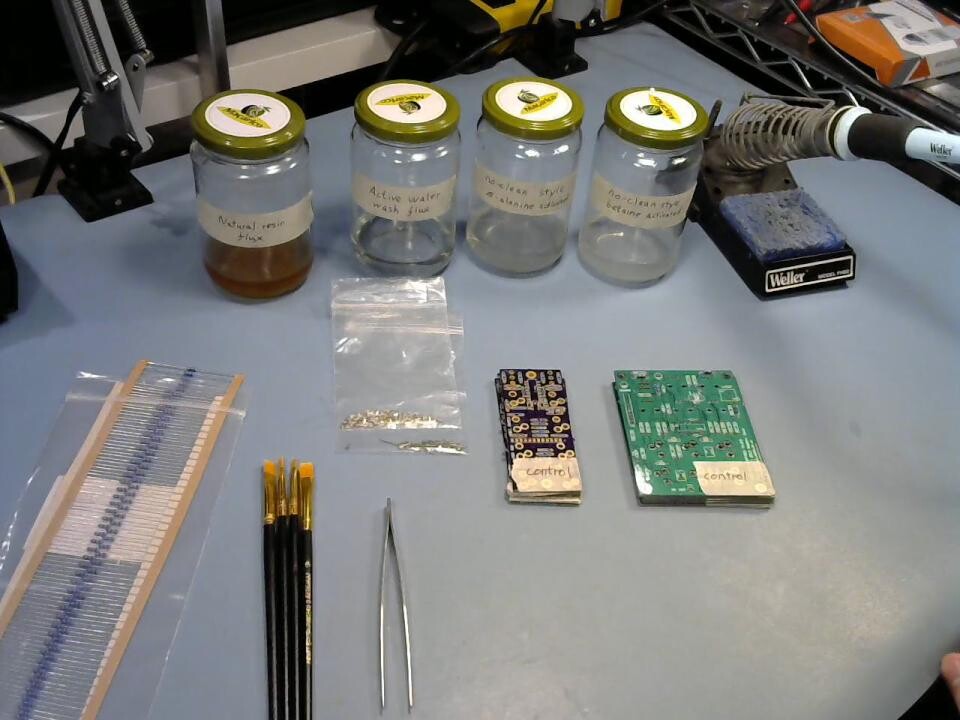

Testing homemade fluxes

In the last four articles (start here) I've gone through a lot of the technicalities of flux: what's in it, how it works, and how to make your own. Now, let's bring it together and try out all these experimental fluxes. READ MORE

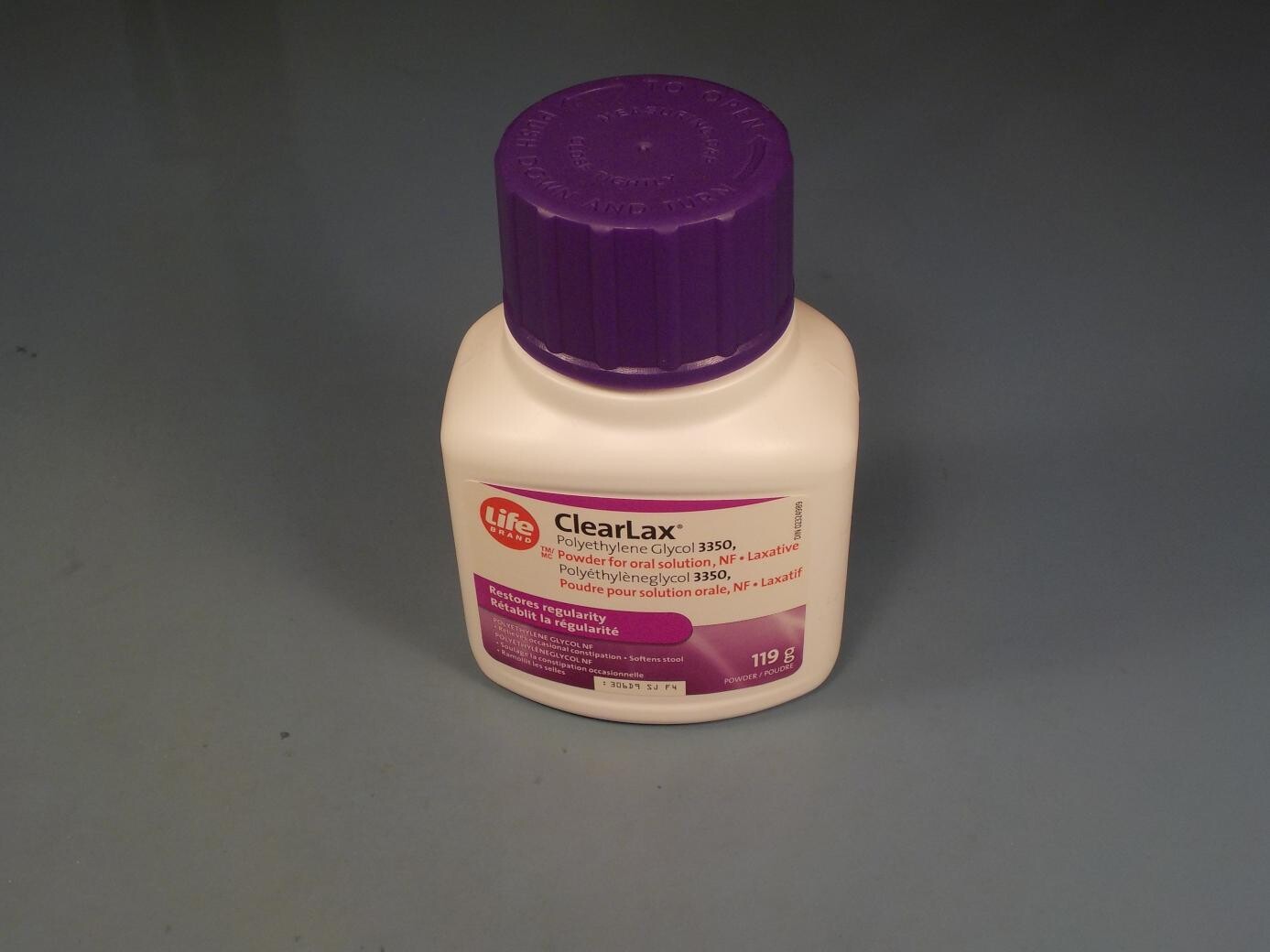

DIY no-clean-style flux

My two previous DIY solder flux formulations are both designed to be cleaned away after use, with alcohol or with water. In both cases the cleaning is more or less necessary: traditional resin leaves a sticky residue that will attract water, and the citric-acid water-wash flux remains active and corrosive at room temperature, so it will damage boards if left in place. But there are many solder joints, such as those involving stranded wire or liquid-trapping components like potentiometers, that cannot or should not be cleaned after soldering. Those mandate a no-clean flux. READ MORE

Make your own water-wash flux

The current trends in electronics are to smaller and smaller surface-mount components; lead-free solder alloys and a diversity of surface platings; higher temperatures which mean soldering must be faster to avoid component damage; and avoiding toxic or environmentally-damaging cleaning solvents. All these trends make traditional solder fluxes, like the one in my last article, less effective or appealing. In this article, let's look at water-wash fluxes, which address some of the issues of the older style. READ MORE

Homemade traditional resin flux

For most of the history of electronics, rosin has been the main ingredient in electronic solder flux. Anybody who learned electronics Back In The Day™ will be familiar with the piney smell of solder smoke. In this second article of the series on flux, we'll look at how to make your own traditional rosin or resin flux. For some background on the chemistry and physics of how flux works, see Part 1: "What is flux?" READ MORE

What is flux?

The details of soldering are always popular discussion topics in synth DIY fora: what kind of soldering iron should I use for building something like a Coiler VCF kit? What temperature? What kind of solder? And that last topic, in practice, is often really a discussion of what flux to use, because flux is usually built into the solder and the differences among fluxes are often the most important differences among solder products. There's been a lot written on recommendations for what kind of flux to use in different SDIY applications, but in this entry I'm going to take a different perspective on flux: the chemistry and physics of the flux itself. What is this stuff that we use every day, and how does it work? In planned future entries, I'll go through flux formulations you can make at home, videos of my own experiments with homemade flux, and so on. READ MORE

Green modular, part 4: Wood, and toxic waste

In this part of the Green Modular series, I'd like to talk about wood, and toxic waste. Part 1 focused mostly on saving energy; in parts 2 and 3 I wrote about metals, and some of the environmental issues related to metals are caused by their toxicity during waste disposal. But there are also other kinds of toxic substances relevant to synthesizers, and those become important during manufacturing rather than at the end of the product's life. READ MORE

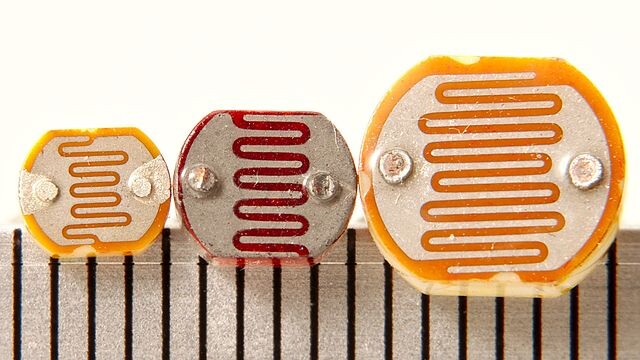

Green modular, part 3: More metal

The RoHS "big three" metals I talked about last time occupy a lot of attention of synthesizer manufacturers because we have specific legal obligations we must meet regarding those metals; but many other metals are also used in building synths, and are also relevant to the environmental footprint of making and owning a synth. Let's look at some more of those. READ MORE

Green modular, part 2: the big three metals of RoHS

In this second part of the series on modular and the environment, I'm going to look at metals. Modular synthesizers are made of many different materials including wood, plastic, and glass, but a significant part of the mass of a synth (or any electronic device) is in metals. Even though metals are often used in small amounts, they often make up a disproportionate fraction of the environmental impact of electronics manufacturing because of all the energy that goes into mining and processing them. There are also unique issues for specific metals: some are toxic, some are rare, some have important social consequences, and so on. I had planned to have just one posting on metals in this series, but it became too long, so I'm going to cover just the "big three" forbidden by RoHS here, and talk about the others in one or more future postings. There's a lot to say about metals. READ MORE