Make your own water-wash flux

The current trends in electronics are to smaller and smaller surface-mount components; lead-free solder alloys and a diversity of surface platings; higher temperatures which mean soldering must be faster to avoid component damage; and avoiding toxic or environmentally-damaging cleaning solvents. All these trends make traditional solder fluxes, like the one in my last article, less effective or appealing. In this article, let's look at water-wash fluxes, which address some of the issues of the older style. READ MORE

Homemade traditional resin flux

For most of the history of electronics, rosin has been the main ingredient in electronic solder flux. Anybody who learned electronics Back In The Day™ will be familiar with the piney smell of solder smoke. In this second article of the series on flux, we'll look at how to make your own traditional rosin or resin flux. For some background on the chemistry and physics of how flux works, see Part 1: "What is flux?" READ MORE

What is flux?

The details of soldering are always popular discussion topics in synth DIY fora: what kind of soldering iron should I use for building something like a Coiler VCF kit? What temperature? What kind of solder? And that last topic, in practice, is often really a discussion of what flux to use, because flux is usually built into the solder and the differences among fluxes are often the most important differences among solder products. There's been a lot written on recommendations for what kind of flux to use in different SDIY applications, but in this entry I'm going to take a different perspective on flux: the chemistry and physics of the flux itself. What is this stuff that we use every day, and how does it work? In planned future entries, I'll go through flux formulations you can make at home, videos of my own experiments with homemade flux, and so on. READ MORE

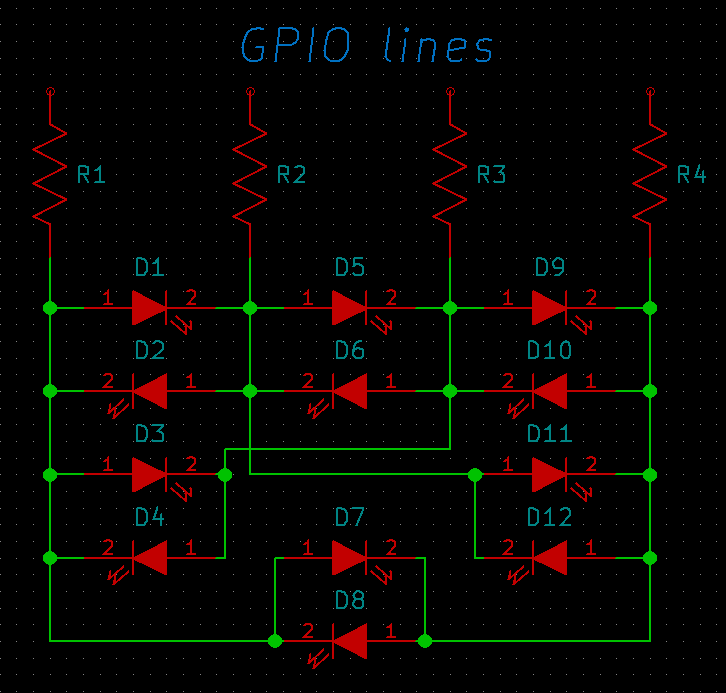

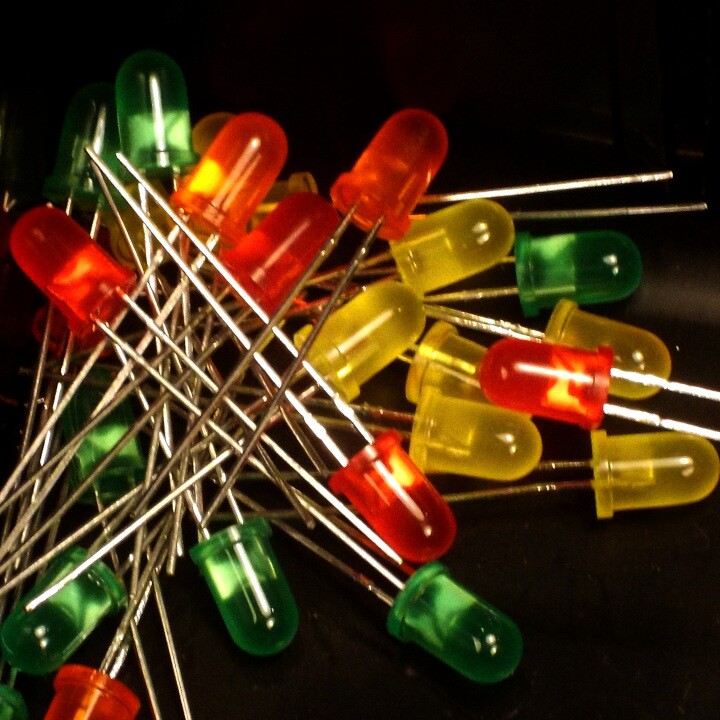

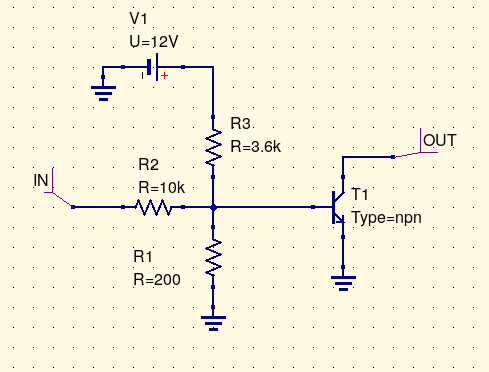

Driving LEDs digitally

In the last entry I described the electrical requirements of LEDs and how to drive them in the context of analog circuitry. When you want to indicate information with the brightness level of a single LED, as in my Transistor ADSR where the LED directly shows the progress of the envelope, it's appropriate to use an analog driver which provides current proportional to the desired light output. But another common use of LEDs is many of them at once, to display information like the shift direction in an octave switch, or even numeric digits in a 7-segment display. For those kinds of applications, it's appropriate to use a digital style of driver circuit. READ MORE

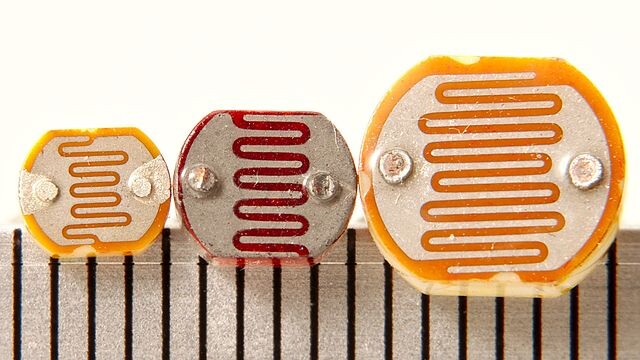

LEDs and analog drivers for them

Light-emitting diodes! They're all over our electronic equipment; but what are they all about, really? The underlying concepts are simple, but there are a lot of frequently-asked questions that show there's confusion among hobbyists about how LEDs work and how to apply them in circuits. Here are some notes on that. READ MORE

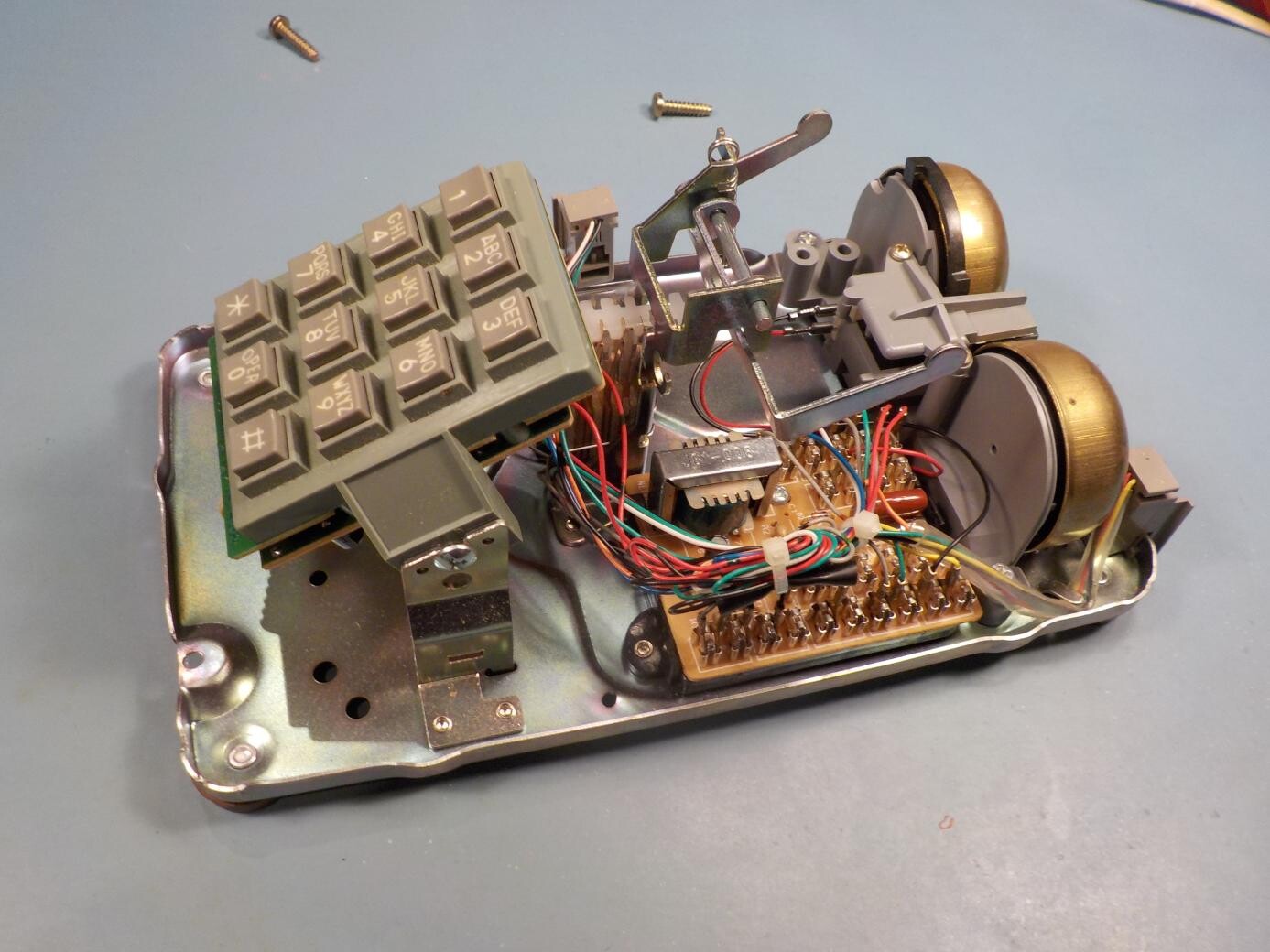

Building a telephone ring booster

I recently switched to a new cable Internet modem, because the cable company (which provides my home Internet service) assured me that the package that came with the new modem would be cheaper for the same service compared to what I'd been paying with my old modem. And that was true, for Internet service. Except for a minor issue of needing to switch my laptop's wireless connection to use dhclient instead of dhcpcd, the Internet connection worked fine. But I quickly discovered a problem. READ MORE

Green modular, part 5: Behind the scenes

In this final part to the green modular series I'll talk about environmental and related issues associated with the modular business, going beyond the manufacturing of the modules themselves. We began this series with RoHS and there may be a temptation to end it there as well: if the actual products are free of a short list of toxic chemicals, they're environmentally friendly, right? Someone who really cares about the environmental impact of buying and using modules should be looking at the whole business. READ MORE

Green modular, part 4: Wood, and toxic waste

In this part of the Green Modular series, I'd like to talk about wood, and toxic waste. Part 1 focused mostly on saving energy; in parts 2 and 3 I wrote about metals, and some of the environmental issues related to metals are caused by their toxicity during waste disposal. But there are also other kinds of toxic substances relevant to synthesizers, and those become important during manufacturing rather than at the end of the product's life. READ MORE

Green modular, part 3: More metal

The RoHS "big three" metals I talked about last time occupy a lot of attention of synthesizer manufacturers because we have specific legal obligations we must meet regarding those metals; but many other metals are also used in building synths, and are also relevant to the environmental footprint of making and owning a synth. Let's look at some more of those. READ MORE

Green modular, part 2: the big three metals of RoHS

In this second part of the series on modular and the environment, I'm going to look at metals. Modular synthesizers are made of many different materials including wood, plastic, and glass, but a significant part of the mass of a synth (or any electronic device) is in metals. Even though metals are often used in small amounts, they often make up a disproportionate fraction of the environmental impact of electronics manufacturing because of all the energy that goes into mining and processing them. There are also unique issues for specific metals: some are toxic, some are rare, some have important social consequences, and so on. I had planned to have just one posting on metals in this series, but it became too long, so I'm going to cover just the "big three" forbidden by RoHS here, and talk about the others in one or more future postings. There's a lot to say about metals. READ MORE

Green modular, part 1: Energy, carbon, and power supply regulators

I'm sometimes asked about the environmental consequences of modular synthesizers. It's an interesting question with a lot of ramifications, and there's a lot of misinformation circulated. That may be inevitable given the nature of this business: synthesizers combine engineering, where hard facts rule, with music, where subjective aesthetics are the order of the day, and it's very easy for someone to start from one bad guess or wrong idea and then follow it into constructing an entire unfounded theory. There's also an unfortunate overlap between the synthesizer hobby and the whole morass of audiophile woo. READ MORE

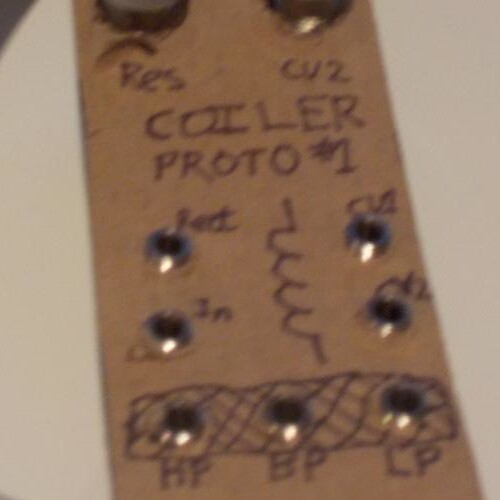

Coiler VCF (pre-) release, vacation

I've been talking for a while about my development process for the MSK 009 Coiler VCF, and now at last it's available for purchase in the North Coast Synthesis online storefront. It's a limited, preliminary manufacturing run, using up a few circuit boards originally bought for prototyping: at this point (December 2018) I have both kits and assembled modules in stock, but only a few of each. Depending on sales of these, I'll order some more PCBs and restock in the new year. READ MORE

Updates and new module development

This posting gathers together a bunch of small news items: new features on the Web site, notably including homegrown videos, the current state of the business, and some ideas I'm working on for future modules. READ MORE

Exponential converters and how they work

Exponential converters are basic building blocks used in many synth circuits, but for many of us, they are incomprehensible black boxes. The basic concept of how an exponential converter works is very simple; but the simplest possible circuit for the purpose has many serious limitations, so it's usual to add several layers of additional circuitry to compensate for different effects and make the overall behaviour more predictable. As a result, the exponential circuits we actually see in common use may look dauntingly complicated to beginning designers, and it may not always be easy to recognize the simple underlying principle. In this article I'm going to build up to a real-life level of complexity starting from the simplest possible exponential converter circuit. READ MORE

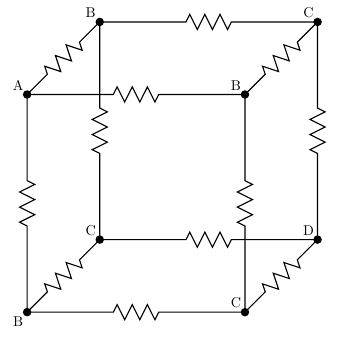

Level up on circuit simplification

In my last entry I talked about the rules for simplifying series and parallel circuits. Two resistors in series can be replaced by one with a value equivalent to the pair of them; two in parallel can similarly be replaced; there are other rules in the same general form for capacitors and inductors (assuming theoretically perfect components); and by applying these rules repeatedly you can simplify complicated circuits down to much simpler equivalents. I also set up an interactive reverse calculator for finding combinations of standard-value components to make up a desired, maybe non-standard, value. READ MORE