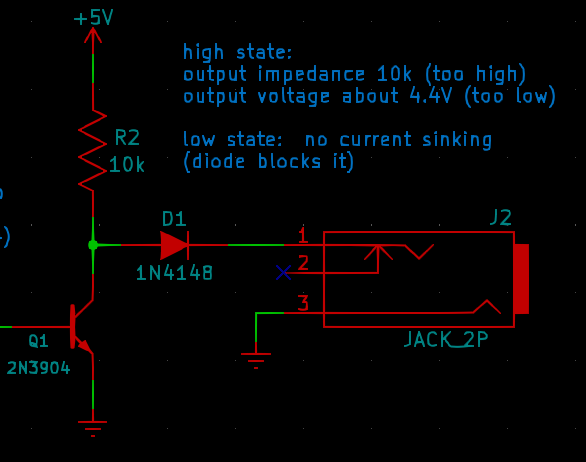

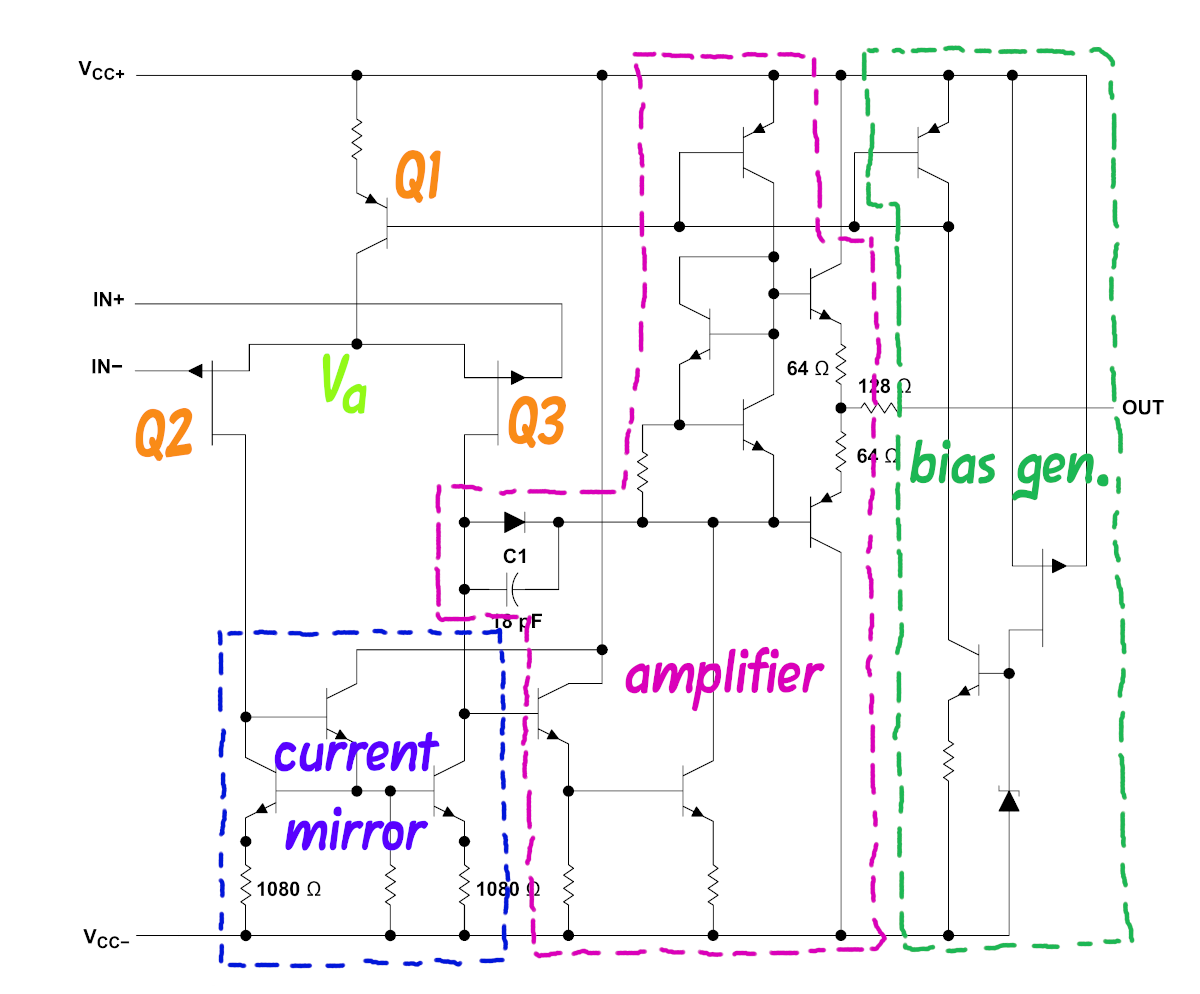

Design mistakes in synth schematics

There are a lot of bad synthesizer schematics on the Web, and it doesn't hurt their popularity. As a designer who tries to get everything right, it's somewhat disheartening to see designs with obvious, simple flaws get built commercially and cited as positive examples - and it's even worse when someone has trouble with one of my modules because they tried to connect it to the latest popular whiz-bang box which has bad levels or whatever and does not play nicely with others. In this article I'm going to talk about some of the problems I see time and time again both in free schematics published for DIY hobbyists, and in commercial modules. READ MORE

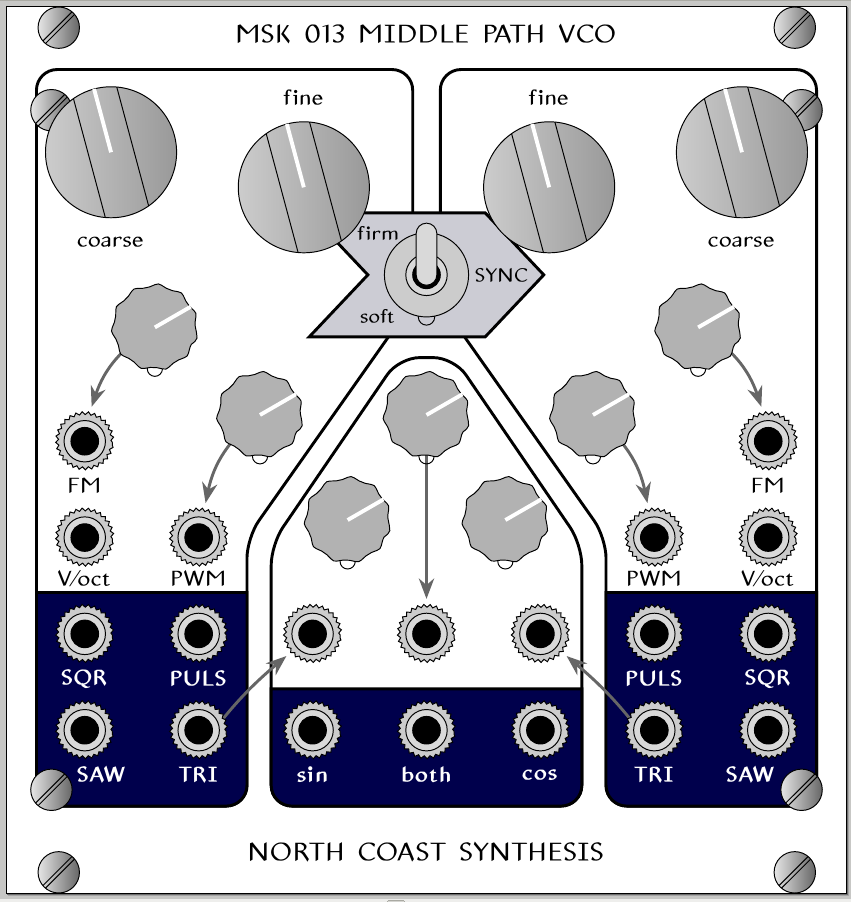

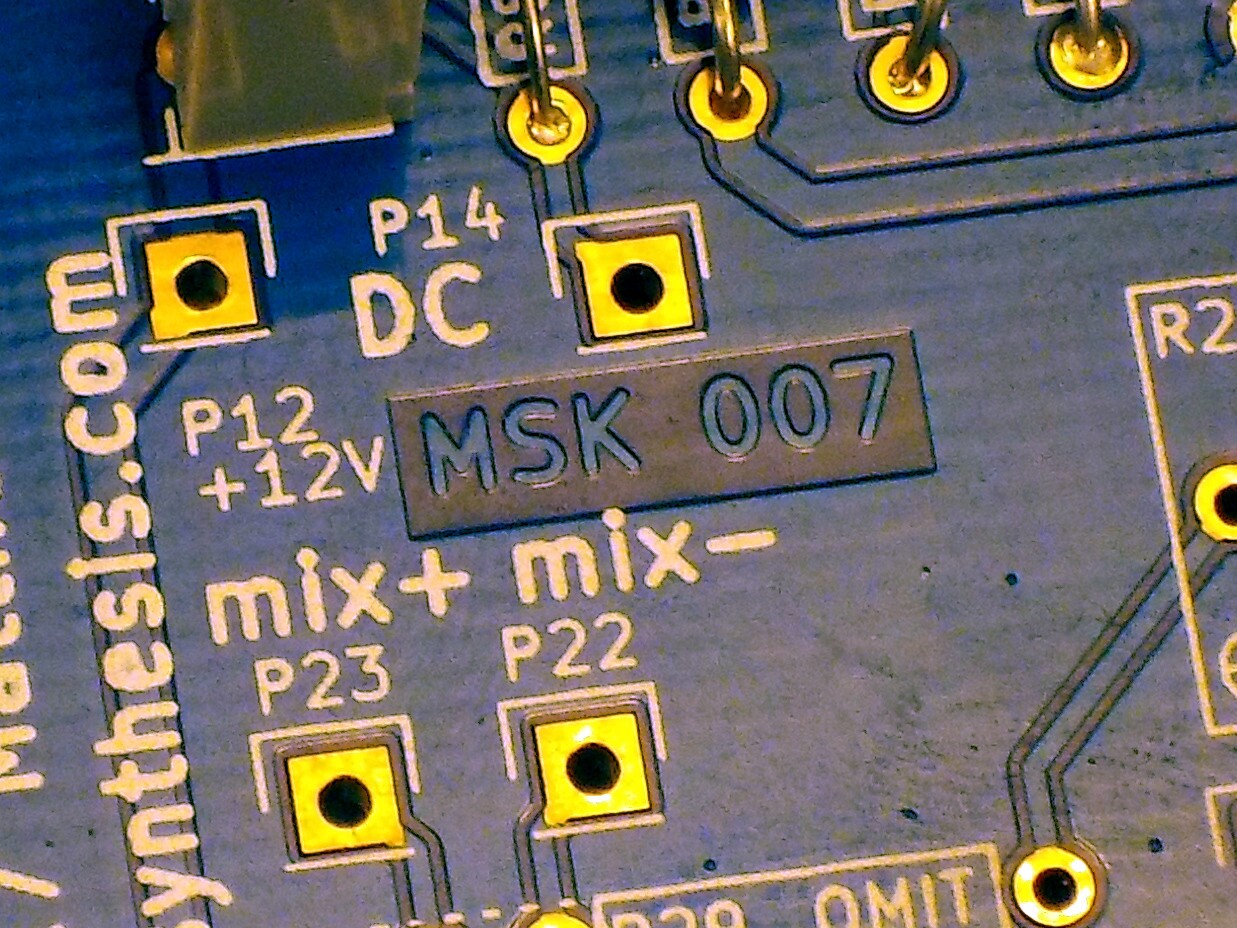

Middle Path VCO development gallery

In the last several weeks I've been working on development for my next product, which I'm ready to announce will be called the MSK 013 Middle Path VCO. It's planned to be a "complex" VCO design with two independent triangle cores that can be synced, and a special waveshaping section based on the Barrie Gilbert sine shaper modified to produce quadrature output; that makes it capable of some through-zero phase modulation effects even though the cores themselves are not through-zero. I've been posting pictures from my development process in other places, and this posting gathers some of those together. READ MORE

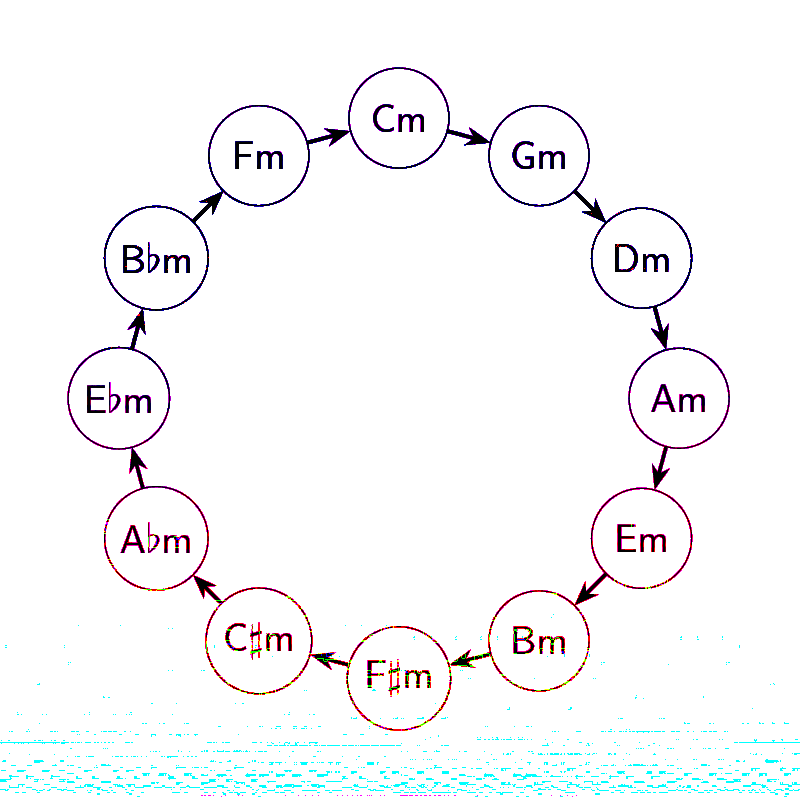

Ambient chord progressions

I get a lot of questions about ambient chord progressions. Actually, I don't get any questions about ambient chord progressions. What I get is search engine traffic from people who were looking for that on the Net, and end up reading my old article about fractal chord progressions, which may or may not be much help to them. READ MORE

Toronto Sound Festival

The Toronto Sound Festival starts tomorrow, November 22, 2019, at "Beverley Halls" (aka the Polish Combatants Association). I'll be there as a vendor, with demos and sales of all my modules and kits. There will also be a lot of other interesting stuff, with other vendors, talks and panel discussions, a "synthesizer petting zoo," a DIY workshop, and a big concert. There'll be a lot of modular there, but the focus is broader, on all aspects of the art of sound. READ MORE

What's the deal with phase reversal?

Alternate title: "This Dad put -10V into a TL074 and here's what happened to his liver!" READ MORE

Tokyo Festival of Modular

The Tokyo Festival of Modular is coming up this weekend, November 16 and 17, 2019, and North Coast Synthesis is a sponsor. I won't be attending in person this year but attendees will receive North Coast stickers and cards with an exclusive discount code. If you're in Japan, this is an event worth visiting. READ MORE

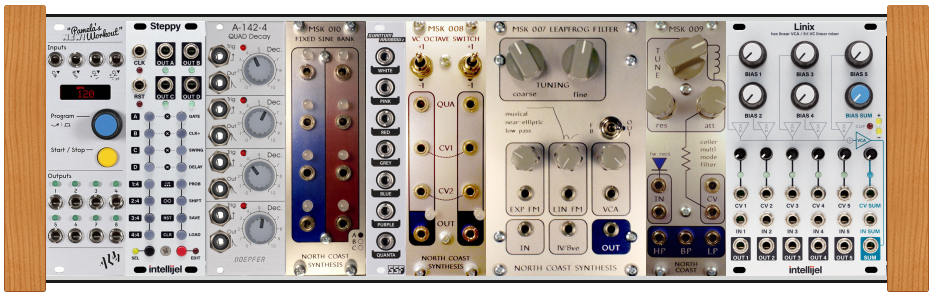

Three suggested systems

Newcomers who are just getting their feet wet with modular synthesis often ask for summaries of how to build a starter system. There are a few things to understand about that. READ MORE

Toronto Pedal and Synth Expo

I'll be exhibiting at the Toronto Pedal and Synth Expo on November 9 and 10, 2019. Drop by to try out North Coast modules in person and pick up a sticker and a discount code. READ MORE

The Truth About Ferrite Beads Will Shock You

Q: The analog synth circuit I'm building calls in the schematic for ferrite beads on the power rails, but it doesn't give any further information. What kind of beads should I use? READ MORE

Designing for adjustment

Testing and adjustment are often underestimated in DIY circuit design. It's all very well to choose exactly the right topology and component values for a circuit; but even with a perfect design on paper or in the simulator, how does one get from there to a physical construction that correctly realizes that design? READ MORE

New look for DIY kits

If you've been following the North Coast Synthesis email newsletter you'll probably know that I've had ongoing quality problems with the knobs I use in most of my products. The main issue is with the setscrews used to hold the knob onto a shaft: in many instances, the threads are stripped, or so weak that they immediately become stripped when tightened, so that it's not possible to attach the knob securely. The problem becomes clear as soon as the knob is installed, so although it is not good in the case of modules I sell assembled, at least with those I can recognize that the knob is bad, replace it, and be sure of shipping a good one to the customer in the finished product. It's more serious with knobs that ship unassembled in my Eurorack SDIY kits, because then it may be the customer who discovers the problem. READ MORE

How to choose component values

When I draw the first draft of a new circuit design, I'll usually work out the topology of the circuit first, and leave out any component values unless it's instantly obvious what they need to be. The topology means which components exist and how they connect to each other, and it's a separate step from deciding their values. I'll come back and fill in the missing values later. There's interaction between these two steps, and I may well modify the topology in later drafts of the schematic as the requirements become clearer, but there's still a definite progression from working on the topology to specifying the component values. READ MORE

More music of the dwarves

I've written before about the music of Dwarf Fortress - not just music to listen to while playing (which is the main thing you can find if you search the Web for this topic) but the music described in-game. The game simulates a procedurally-generated fantasy world full of different species of intelligent creatures (dwarves, elves, humans, etc.); game characters sometimes are described as playing music; and for each simulated culture, the game software generates a description of that culture's music. READ MORE

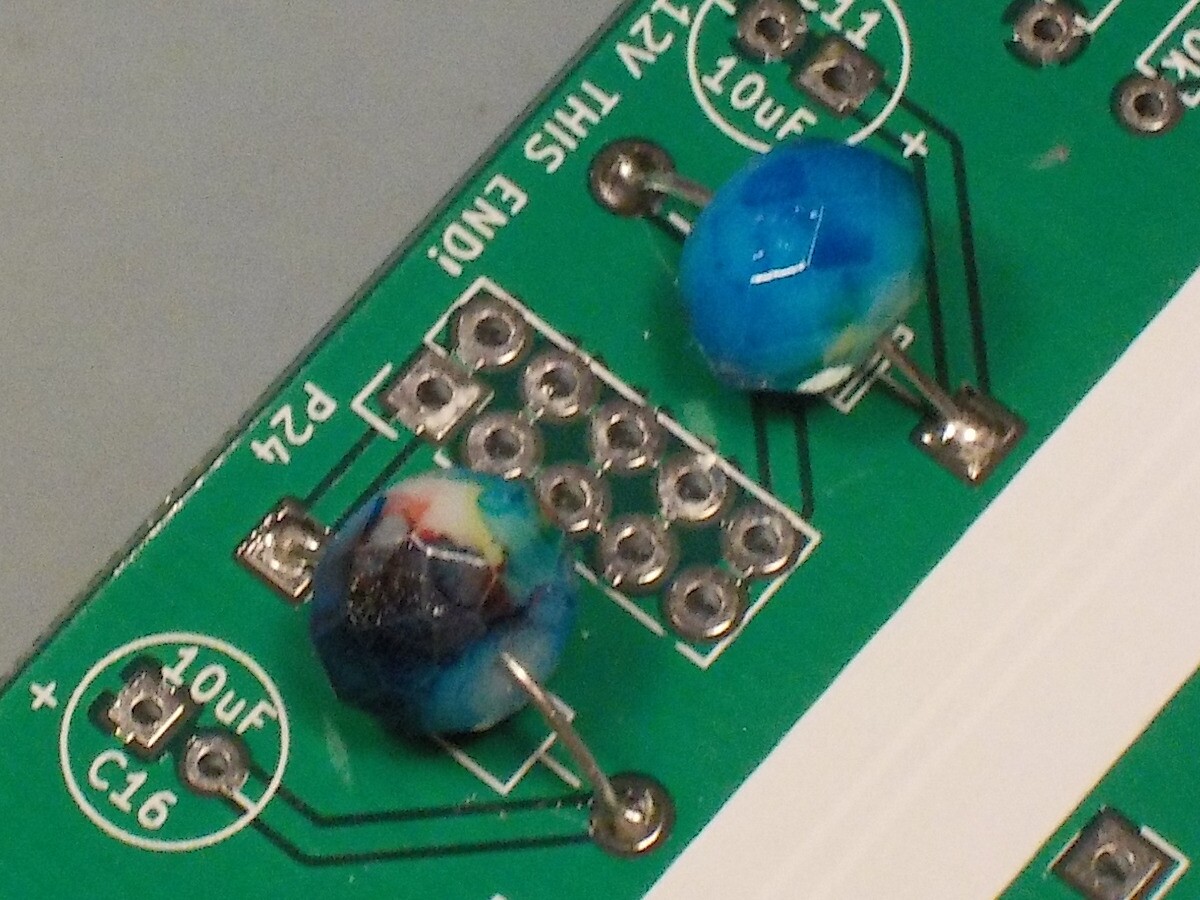

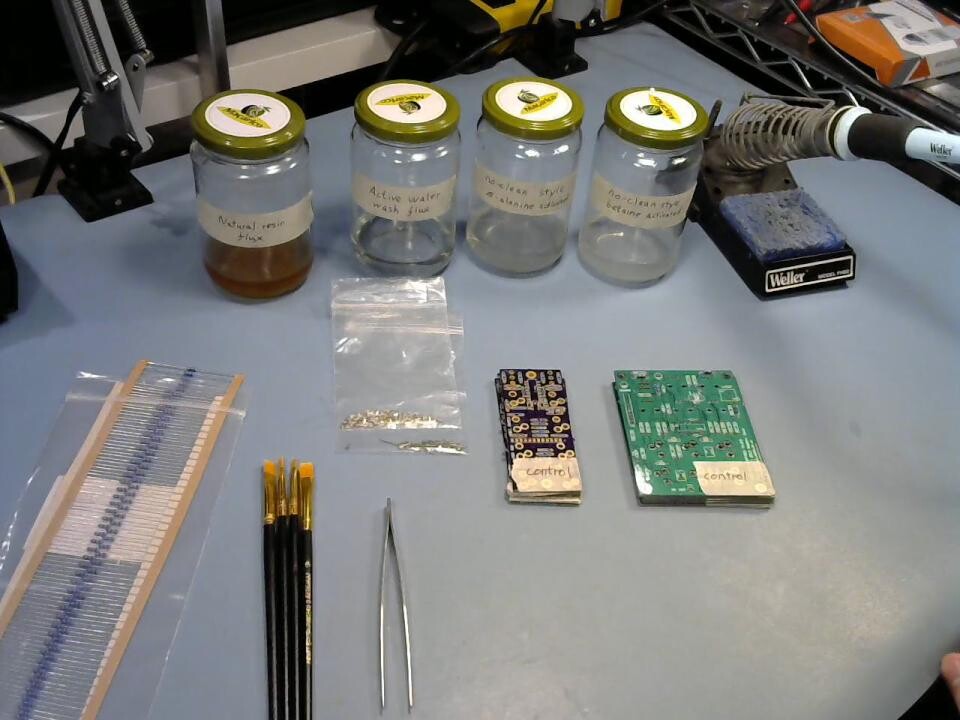

Testing homemade fluxes

In the last four articles (start here) I've gone through a lot of the technicalities of flux: what's in it, how it works, and how to make your own. Now, let's bring it together and try out all these experimental fluxes. READ MORE

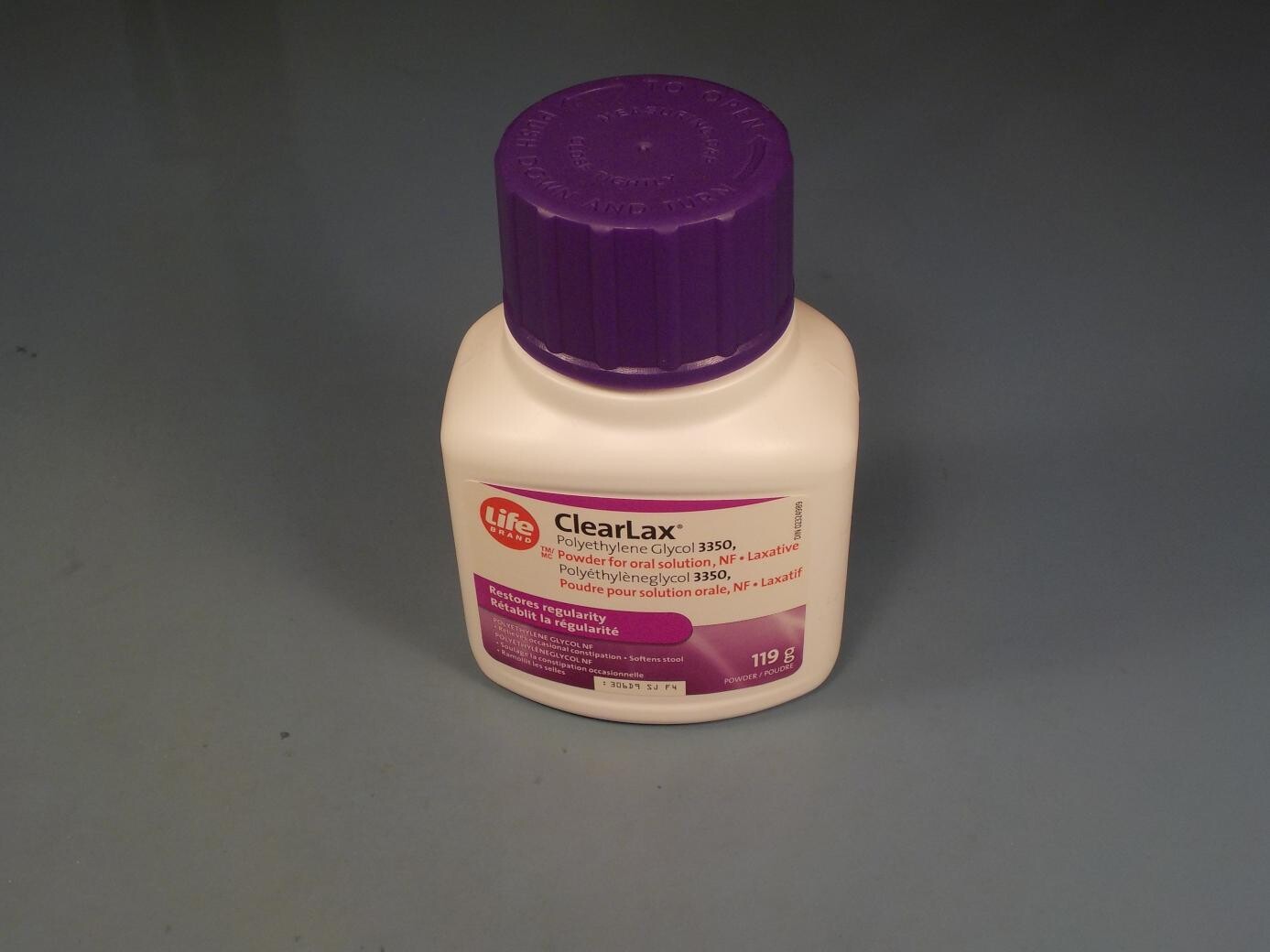

DIY no-clean-style flux

My two previous DIY solder flux formulations are both designed to be cleaned away after use, with alcohol or with water. In both cases the cleaning is more or less necessary: traditional resin leaves a sticky residue that will attract water, and the citric-acid water-wash flux remains active and corrosive at room temperature, so it will damage boards if left in place. But there are many solder joints, such as those involving stranded wire or liquid-trapping components like potentiometers, that cannot or should not be cleaned after soldering. Those mandate a no-clean flux. READ MORE